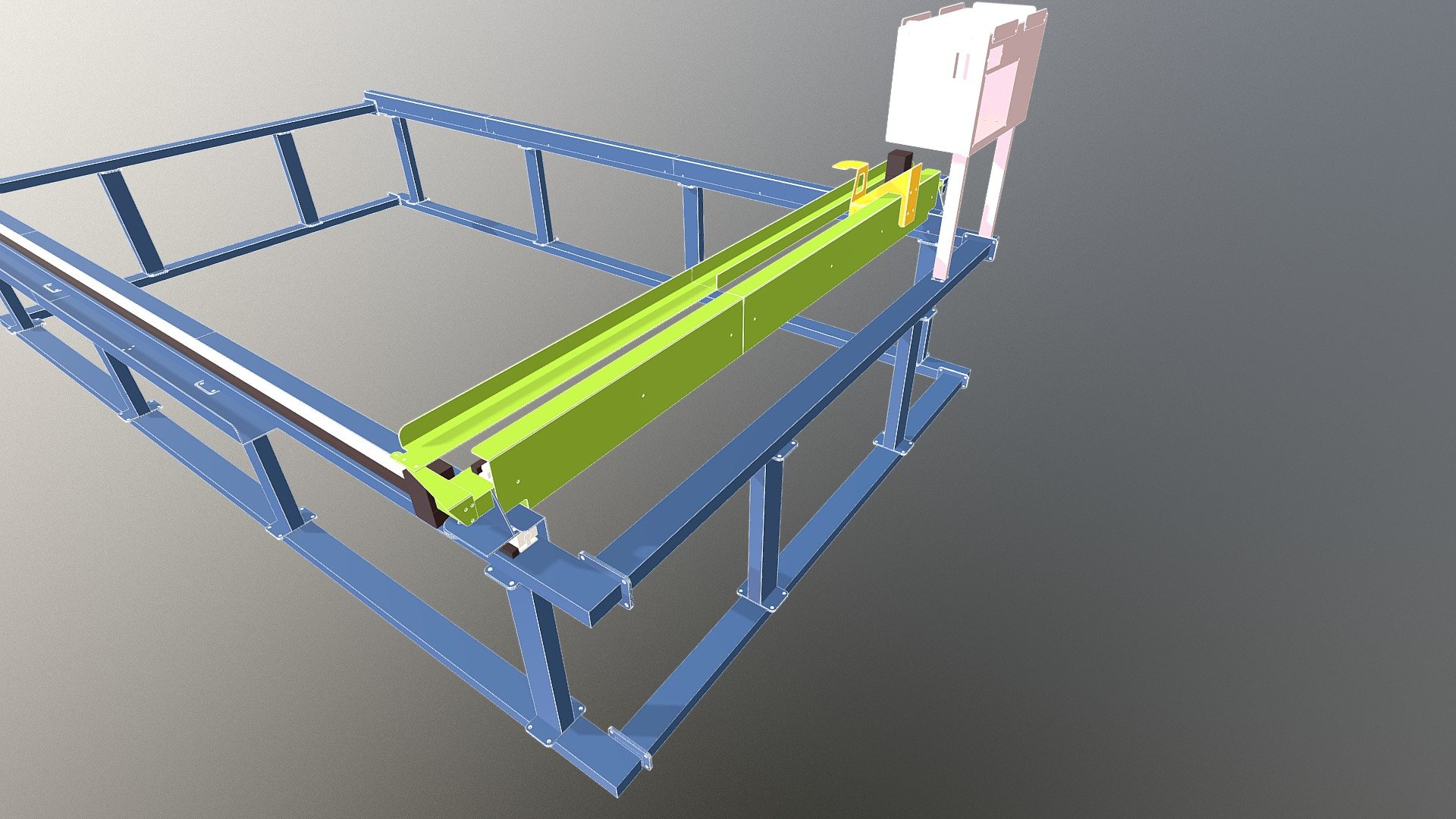

ЧПУ ПЛАЗМОРЕЗ ИВАН

sketchfab

Building a CNC Plasma Cutter from Scratch, the Ultimate DIY Project If you're an adventurous individual with a passion for metalworking and a penchant for innovation, building your own CNC plasma cutter is an exciting project to take on. With the right guidance, creating a custom cutting machine can be a rewarding experience that opens up new possibilities in the world of metal fabrication. The process begins by researching different types of CNC plasma cutters available on the market. This involves studying various designs and architectures, as well as understanding the underlying technology behind each model. By gaining a deep understanding of how these machines work, you'll be able to design your own custom solution that meets your specific needs and requirements. Once you have a clear idea of what you want to achieve, it's time to start building your CNC plasma cutter. This involves sourcing high-quality materials and components, such as precision-cut steel plates, stainless steel rods, and durable electrical wiring. With the right tools and equipment at your disposal, you'll be able to bring your design to life and create a functional cutting machine. Throughout the build process, it's essential to focus on precision and accuracy. This involves carefully measuring and cutting each component to ensure that they fit together seamlessly. By taking the time to get everything just right, you'll end up with a reliable and efficient cutting machine that produces high-quality results. One of the most significant benefits of building your own CNC plasma cutter is the ability to customize it to suit your specific needs. This allows you to tailor the machine's design and functionality to fit your unique requirements, whether it's for personal use or commercial applications. By having complete control over the build process, you'll be able to create a cutting machine that meets your exact specifications. As you progress through the build process, it's essential to stay organized and keep track of your progress. This involves documenting each step of the way, including measurements, cuts, and assembly. By keeping a detailed record of your work, you'll be able to reference back to it later if needed and make any necessary adjustments. In conclusion, building a CNC plasma cutter from scratch is an exciting project that requires patience, dedication, and attention to detail. With the right guidance and resources, creating a custom cutting machine can be a rewarding experience that opens up new possibilities in the world of metal fabrication. https://www.forumhouse.ru/threads/431933/

With this file you will be able to print ЧПУ ПЛАЗМОРЕЗ ИВАН with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on ЧПУ ПЛАЗМОРЕЗ ИВАН.