Z Axis Synchronizer For Hesine 505

pinshape

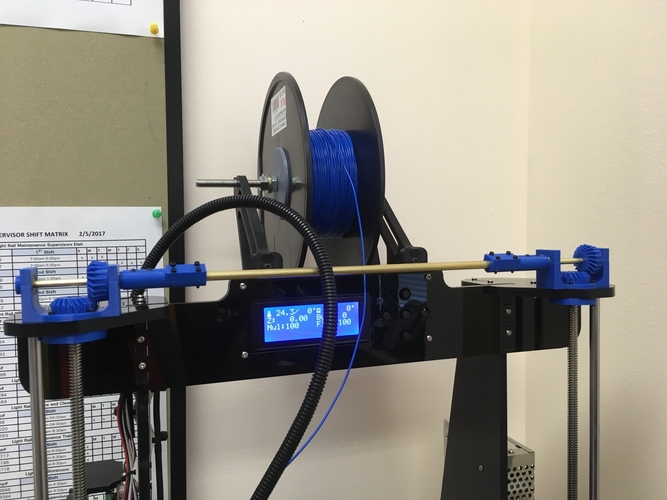

Human: Z Axis Synchronizer for the Hesine 505 My Printer (Hesine 505) has a Z stop only on one side, which causes the other side to get lost during power up, requiring me to re-level before printing, a tedious process. I created this double miter gear arrangement to keep both Z axes in sync at all times. To avoid using a continuous long GT2 timing belt due to its high slop factor, I opted for 20-degree Angle type Miter gears that are free from play and smooth running. The entire assembly is easy to adjust once installed. I have provided two drill templates for aligning the eight holes of the 2-56 Socket Head Cap screws. All parts, including the gears, can be printed with no overhangs using PLA with four top and bottom layers, and four perimeters at 100u per layer. With this setup, my extruder always maintains the proper height and parallelism to the build surface without needing a bed leveling routine in my firmware. The gears are secured to their shafts using four 4-40 set screws. The shafts consist of K&S Brass tube with a 3/16" OD for the left gear and a 1/4" OD for the connecting shaft. The 3/16" Brass tube needs to be sanded slightly to fit inside the 3/16" ID X 1/2" OD by 0.200" Wide Ball Bearings (I used standard Router pilot bearings here). The Z Lead screws had to be raised to mount the right-hand miter gear, which is supported by two 8 x 12 x 3.5mm Stainless Steel Shielded Ball Bearings from McMaster Carr PN# 7804K115 at $8.03 each. The Z Lead screw support bearings are housed in the "Lower 8mm Bearing Holder.STL" and secured to the bottom of the top acrylic plates using four 2-56 X 3/4 Socket Head Cap Screws for each tower. The long couplings (5mm x 8MM) are used to raise the Z Lead screws, which are secured with six 32 set screws. Use the collars to secure the 3/16" shaft from sliding laterally and to hold the gear in mesh. The split couplings have caps to hold the 1/4" Brass connecting shaft in place using two 2-56 X 1/4" SHCS. This arrangement works smoothly and is totally free from play. Note: when tapping PLA, four perimeters are required, and tapping should be done by hand and slowly to avoid heat build-up. I have also included the "X Axis End Plate.stl", which will support the right-hand Z slide from being pulled inwards towards the left side due to X Belt tension. This pulling bows the Z Vertical rods inward and limits the tension you can apply on the X Belt. Print with PLA and tap two 6-32 holes, then use two 6-32 x 3/4" screws with jam nuts to apply pressure to the X rods. The plate is simply CA glued into the side of the right-hand Z slide as shown in the photo.

With this file you will be able to print Z Axis Synchronizer For Hesine 505 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Z Axis Synchronizer For Hesine 505.