Yet Another PowerSpec/MakerBot/FlashForge/CTC Glass Bed Corner Brace

thingiverse

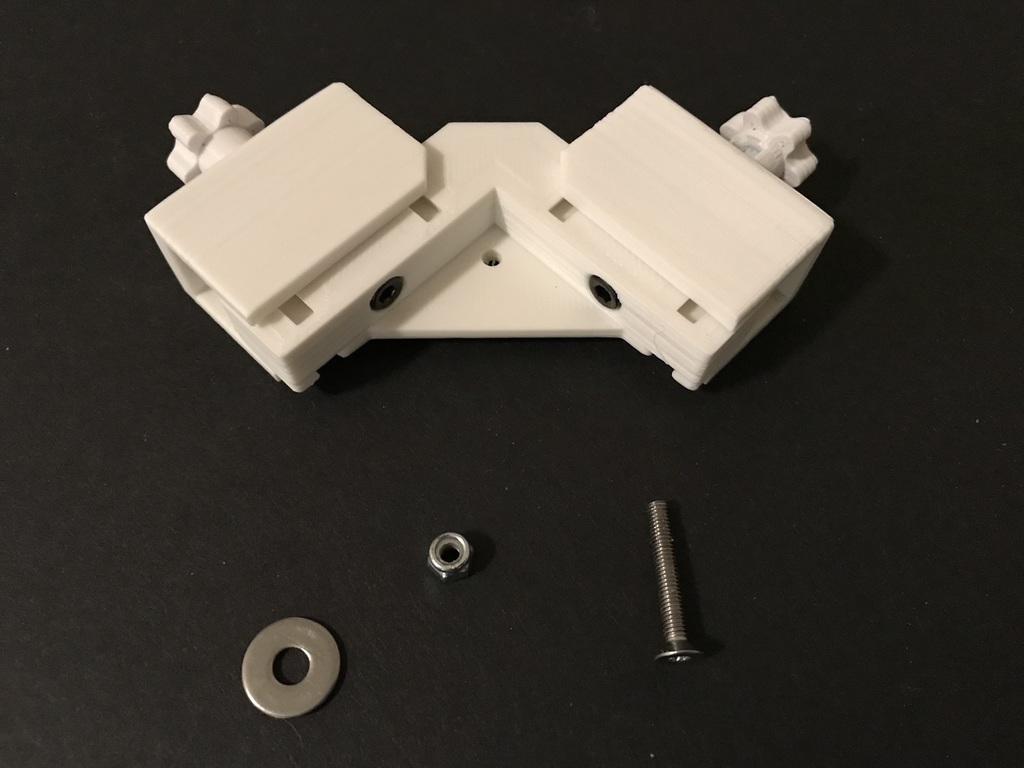

I have a PowerSpec 3D Pro printer (original model) and switched to glass bed printing several years ago. Since then, I've been searching for a reliable glass bed corner brace/bracket that securely holds the glass firmly without failing after an unreasonable time frame. I've tried many different designs available on Thingiverse, but they didn't meet my expectations - they'd melt, crack, or deform quickly, causing the glass to shift out of place. I designed this corner brace based on three key principles: 1. Easy and fast swapping of glass plates. 2. Increased surface area for contact with the edges of the glass plate, eliminating the issue of chipped glass caused by designs using M3 socket screws. 3. Ability to securely hold oversized or undersized glass plates. The Components: There are four printed components: the support bracket, left and right side slides, and the thumbscrew. To complete a corner, you'll need: (1) Support bracket (1) Left slide (1) Right slide (2) Thumbscrews Additional components include: (2) M3 x 35mm Hex socket head cap screws (4) M3 Hex Nuts (2) 7/32" x 11/16" Compression springs (Optional, but recommended for optimal performance) (1) Original countersunk screw and nut from your aluminum build platform. I upgraded the nut to a nylon lock nut. (1) Metal washer for use with the original countersunk screw and nut (Optional) Assembly Instructions: I omitted the mounting hole for attaching the support bracket to the aluminum build platform, as my platform's holes are not uniform. Before assembling each corner, I drilled a hole in each bracket using a #33 or .113" drill bit. Photos detailing the assembly process are included. If you have questions, feel free to ask in the comments and I'll do my best to help. Results of Testing and Use: I've been using four of these braces on my printer since January this year. After revising the design in February, I replaced the originals with updated parts. The originals worked exceptionally well until I swapped them out, and the new parts have performed even better over the past three months. I've done a lot of printing lately, using both ABS and PLA materials at build platform temperatures between 50-110 degrees Celsius.

With this file you will be able to print Yet Another PowerSpec/MakerBot/FlashForge/CTC Glass Bed Corner Brace with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Yet Another PowerSpec/MakerBot/FlashForge/CTC Glass Bed Corner Brace.