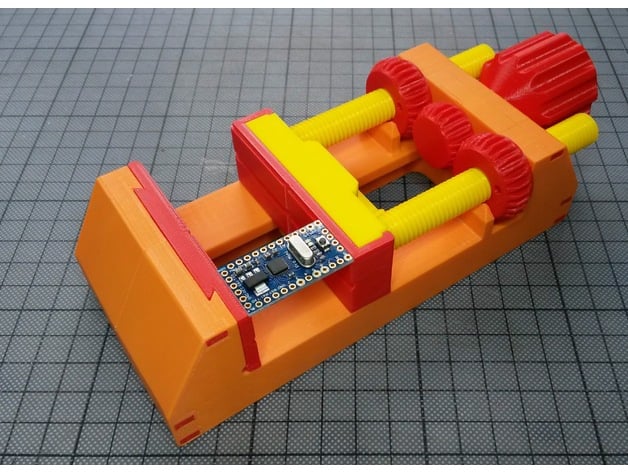

Yet ANOTHER Machine Vise

thingiverse

This is a remarkably robust 3D-printable machine vise that's 100% 3D-printed - no screws or other hardware pieces are required to hold the individual components together. The pieces simply clip and snap into place. It's essential to consider forces and material properties from the outset when designing mechanical objects, as evidenced by this vise's design. For insight on proper design techniques, watch my video at https://youtu.be/mziT7KV-fRI, which also includes a step-by-step guide to assembling this vise. For 3D-printing, it's recommended to print with 3 shell layers and 35% infill - more than that won't make the vise any stronger. The forces required for clamping a workpiece are only active at the outer surface, after all. A layer height of 0.15 mm is suitable (although printing screws might be better done with 0.1mm layers). No support material is needed, and it's best to use a 0.4 mm nozzle. Assembly instructions can be found here: https://jig.space/view?jig=1216 (thanks to http://www.thingiverse.com/greenlig). I designed this vise using Fusion 360: http://a360.co/2juhSUG. If you're having trouble printing the threaded rods vertically, try this version of the sliding jaw with horizontally printed rods: http://www.thingiverse.com/thing:2123529. For those interested in standards and curriculum alignment: * NGSS (Next Generation Science Standards) Now, let's take a closer look at mechanical objects and 3D-printing. In most cases, people try to 3D-print common mechanical objects without much thought for their design. However, these traditional shapes often aren't 3D-printable, or they may not work as intended even if they are printed successfully. That's why it's crucial to adapt the design of a mechanical object according to its future use. If you're familiar with CAD software and designing objects for 3D-printing, I recommend considering the unique material properties of 3D-printed parts. This will help ensure that your designs are robust and functional. Here's what we'll be covering in this lesson plan: * Watch my video on YouTube to learn how to design better 3D-printable mechanical objects Materials needed for this activity include a spool of PLA or PETG filament, a 3D printer, and some CAD software (such as Fusion 360 or Tinkercad).

With this file you will be able to print Yet ANOTHER Machine Vise with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Yet ANOTHER Machine Vise.