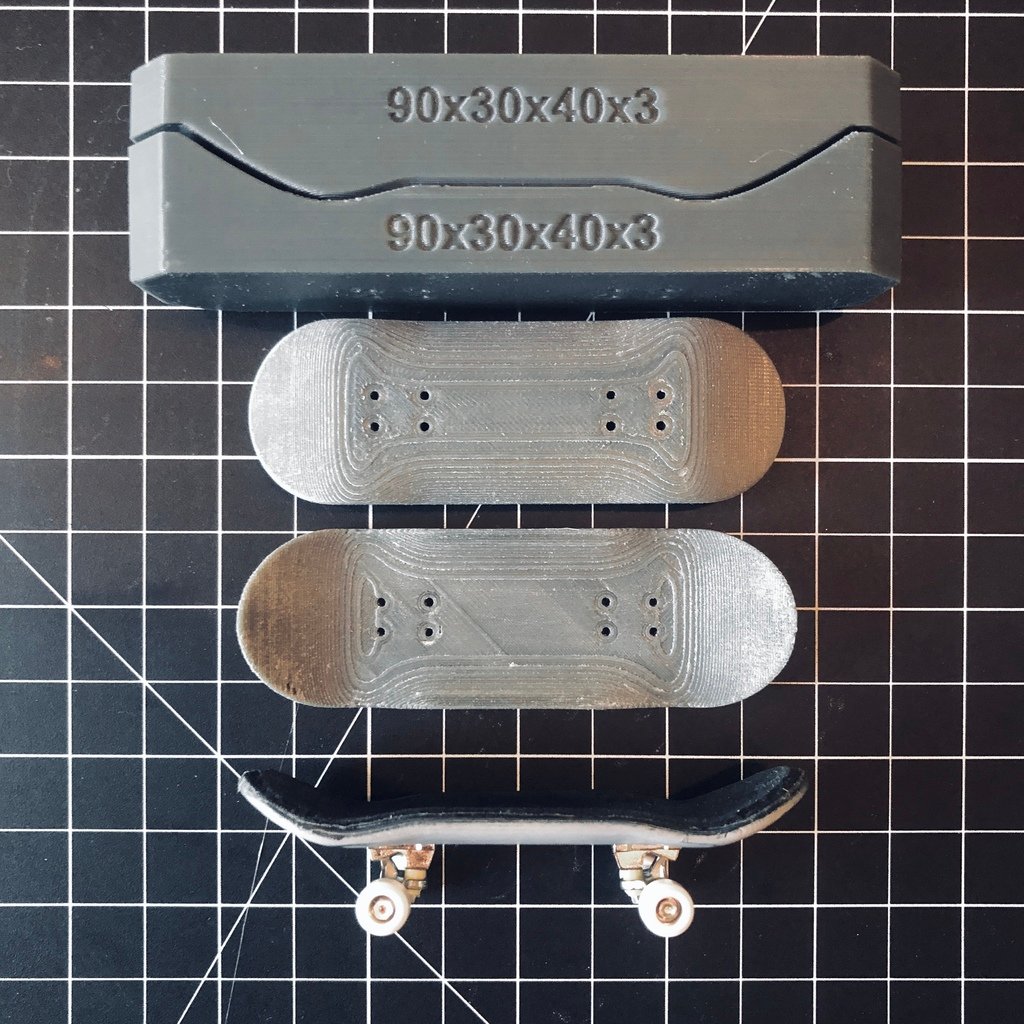

Yet Another Fingerboard (Boards, Moulds, Shapers, Wheel Nut)

thingiverse

It appears you're detailing your process for creating miniature skateboards using 3D printing and wooden veneers. Here's a breakdown of your steps: 1. **Printing Small Components**: You used PETG for printing due to its durability compared to PLA or ASA, which might be too brittle for these small components. The components are roughly the size of glitter but were printed with a standard 0.4mm nozzle. 2. **Creating A Board**: - **Choosing Veneer**: You opted for thin hickory veneer as it was available, though maple would have been preferable due to its hardness and durability. - **Thickness and Dimensions**: For the larger board, you used 107x40mm veneer pieces, and for the smaller one, 100x35mm. The minimum size required is about 102x35mm for the larger board and 95x32mm for the smaller one. 3. **Assembly**: - **Glue**: You used Titebond III as it was readily available and you've had positive experiences with it in making full-sized skateboards. - **Clamping Time**: The glue needs to be clamped for a few hours before the board is considered durably glued and formed. This could be due to the softness of the hickory veneer absorbing more moisture from the glue. 4. **Finishing**: - **Drilling Holes**: You use a 1.5mm drill bit in a drill press for drilling holes, keeping the board in the mould for maximum accuracy. - **Countersinking**: After drilling, you use a countersink bit to finish off the holes. Your process involves careful consideration of material selection and precision in dimensions and assembly. While it seems like your boards turned out well, there are considerations regarding the durability of the glue and veneer that could be explored further for improving the quality of your miniature skateboards.

With this file you will be able to print Yet Another Fingerboard (Boards, Moulds, Shapers, Wheel Nut) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Yet Another Fingerboard (Boards, Moulds, Shapers, Wheel Nut).