YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER

thingiverse

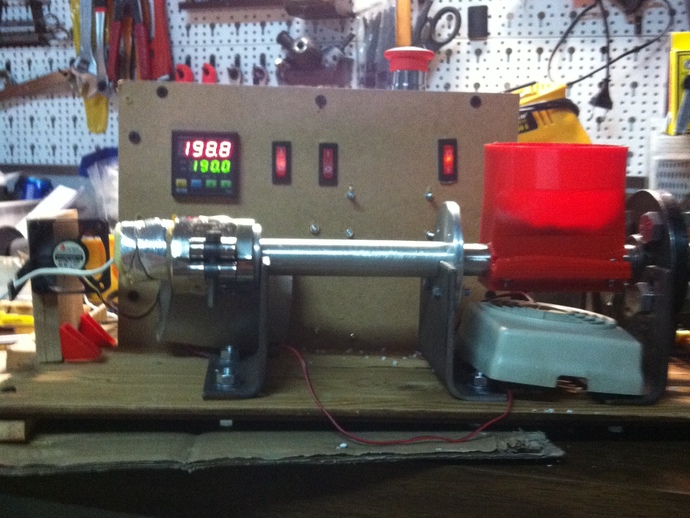

My aluminum extruder derivative is finally working perfectly! After following Mr. Lyman's filament extruder V2 and incorporating Bottleworks' ideas, I was able to successfully extrude ABS filament for 3D printing. Test prints (check photos) demonstrate the potential of home-extruded ABS. In the 'Instructions' section, I explain how I tackled various issues, including placing an old monitor cooling fan to cool the hopper and moving the temperature sensor near the nozzle for better control. Additionally, I provide general tips for extruding, such as adjusting temperatures based on plastic viscosity and drying ABS at 80°C for 1-2 hours to remove moisture. Overall, this project showcases the feasibility of creating one's own filament for 3D printing at home with careful planning and attention to detail.

With this file you will be able to print YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on YALFE - YET ANOTHER LYMAN'S FILAMENT EXTRUDER.