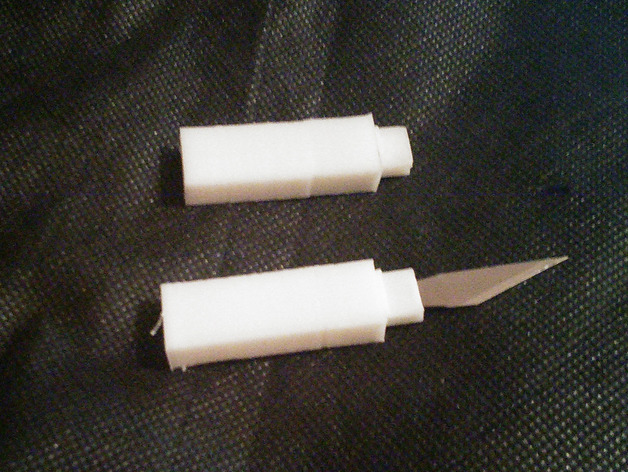

xacto #11 blade sheath and hilt

thingiverse

I replaced my handle so I fabricated these to secure the remaining blades. The print requires careful navigation since you must halt precisely at the correct layer and embed a razor-sharp blade into scorching hot plastic within a sizzling machine. So be cautious not to trigger a catastrophic outcome. Repetier elegantly addresses this pause with a @pause command strategically inserted on a specific layer. It appears to print smoothly at .3mm slice height with .3mm infill density settings. I maintain the blades on the printing bed, allowing them to heat up until it's time for insertion. The secret to this endeavor is, as with numerous penny bottle opener designs, pausing at precisely the right layer. Ideally, that would be before transitioning to layer placement over the 0.5mm blade slot. Here, I place a Repetier Host @pause command in the g-code, which sounds an ear-piercing alarm for me. Upon activation, I immediately re-home Y-axis movement, secure the blade, and resume printing operations. Be warned that this method demands unflinching bravery, considering the staggering number of possible errors leading to potentially disastrous consequences – including property damage, life-altering accidents, and severe limb trauma. If you're unwilling to confront such risks head-on, abandon your plans; but for those willing to face them fearlessly, proceed with great caution and at your own peril!

With this file you will be able to print xacto #11 blade sheath and hilt with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on xacto #11 blade sheath and hilt.