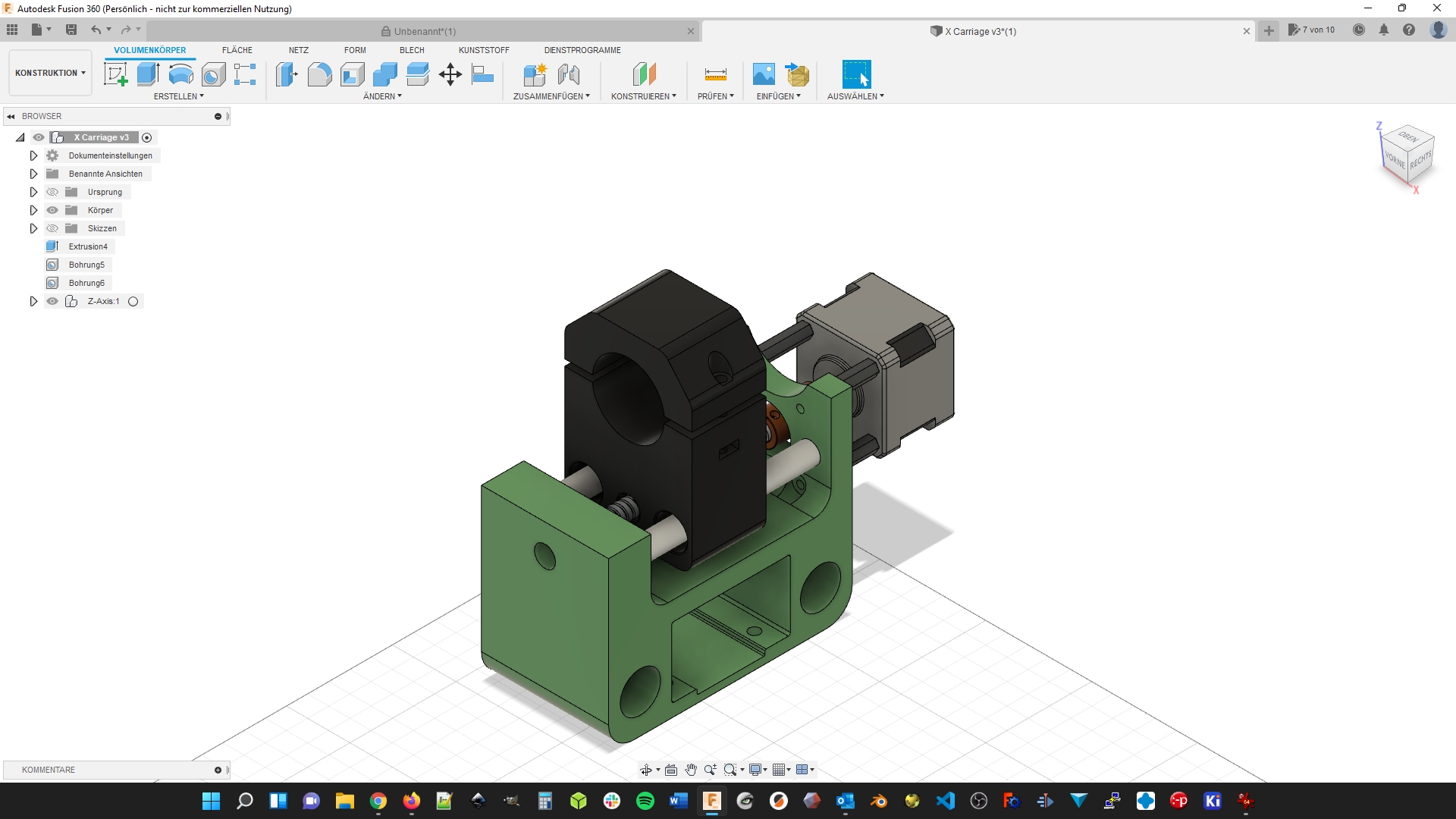

X/Z axis upgrade for 3018 CNC

thingiverse

<b>An X/Z axis upgrade for the 3018 CNC machine.</b> For 16 mm linear shaft X-axis. For 10 mm linear shaft Z-axis. Extra strong design. An 80x40x4 millimeter thick aluminum plate should be attached to the rear side. This increases the rigidity again. The carriage should be moved with a threaded spindle TR 8X1.5 and a trapezoidal thread nut 8X1.5 with an aluminum housing (https://www.dold-mechatronik.de/Trapezgewindemutter-8x15-R-Rotguss-mit-Aluminiumgehaeuse). - 4 (or 2) sintered bushings 16x19x19 for the X-axis - 4 (or 2) sintered bushings 10x15x15 for the Z axis - The Z axis requires two 10x100mm linear shafts. <b>Sintered bronze bearings must run almost perfectly parallel to each other so that they do not tilt. Because most 3d printers are not perfectly adjusted, it can be advantageous to use only one bearing per axis.</b> The component should be printed in at least PETG or ABS. The filling should consist of a honeycomb structure with 40% filling. At least 6 massive layers everywhere. A print speed of 30-40mm per second and a layer height of 0.2mm is recommended. Due to this and the honeycomb filling, the printing process can easily last 20 hours or more.

With this file you will be able to print X/Z axis upgrade for 3018 CNC with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on X/Z axis upgrade for 3018 CNC.