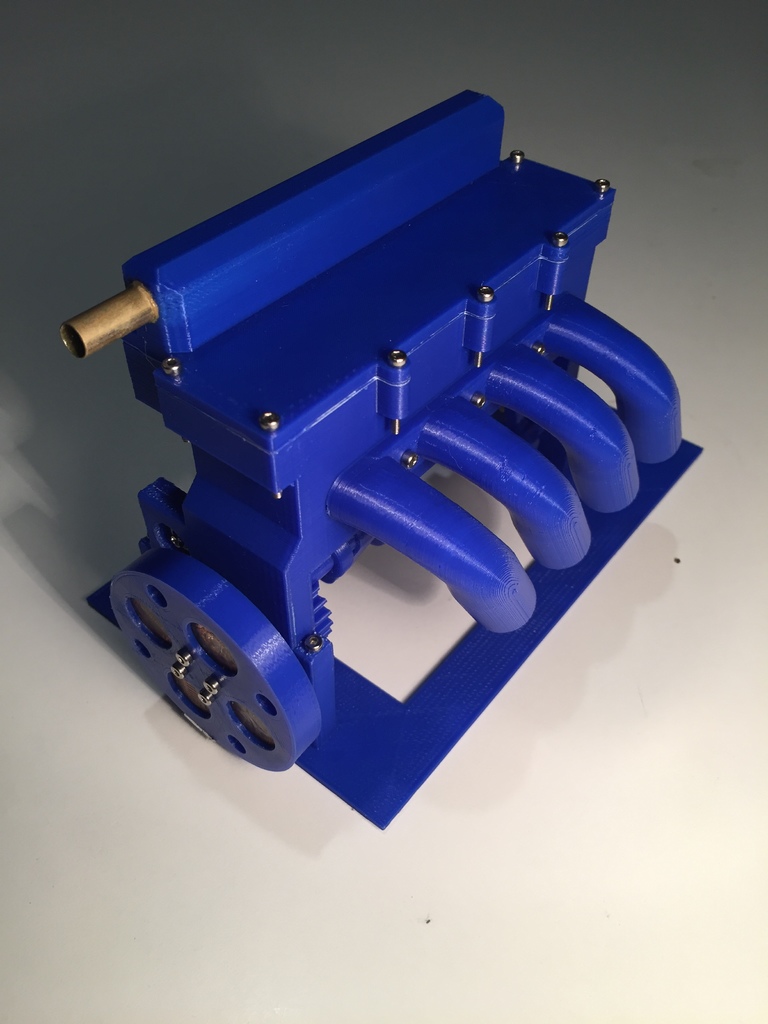

Working 4 Cylinder Air Engine Model

thingiverse

Edit as of 4-16-19: -Revised cam ends, making them shorter so 50mm bolts fit deeper. -Revised flywheel hub to have a collar preventing bearing from pushing down on it -Added crank spacers keeping connecting rods centered -Added small amount to piston diameter for easier sanding, reducing scratchiness -Shortened crank gear by 1mm for tolerance in the block This is a small 4 cylinder air engine I designed and built using 3D printed parts and store-bought bolts and springs. Assembly instructions are available for sale, guiding you through each step. To see more about this engine and a video of it running, check out my Instagram page @CompressedCreations I apologize for the parts not being faced correctly to print when uploaded to a slicer; simply turn them to the correct orientation and they will print. I used 3D Printer OS to slice all files and include specs in instructions. Some basic knowledge is needed to assemble this engine, as I refer to components by name and some terminology may be unfamiliar without experience. It's not extremely complex but requires a general understanding of engine mechanics. Engine Specs: ~1000 RPM @ 1psi (lung pressure) Max RPM unknown but likely around 5000 21.5 CCs of displacement Bore: 19mm Stroke: 19mm Required tools for assembly: -Sandpaper, 200+ grit; I recommend using 400 -1.5mm Allen wrench -Small Phillips screwdriver -Razor blade (Xacto knife recommended) -Small amount of epoxy/super glue Parts Required: -M2x16mm bolt (10) -M2x50mm bolt (2) -1mm rod ~25mm (4) -3mm rod ~18mm (4) -M2x22mm bolt (4) -M4x15mm spring (4) -M2x12mm bolt (8) -M2 nut (14) -6mm airsoft BB (4) -8mmx2mm O-ring (4) -5x11x4mm bearing (4) -.25" brass tube (1") This engine requires a significant number of parts, which can be expensive to purchase in minimum quantities. I've found the cheapest options for these parts and estimated it would cost over $70 to buy them all due to shipping from various places. I have full part bundles and instructions available for sale here: https://compressedcreations.bigcartel.com This will save you time, money, and ensure you get the exact parts used in this engine. I'll also cut necessary pieces to the closest spec possible if you purchase it from me; the cost is $21 for all necessary parts and $2 for 3-5 day shipping. This engine is designed as a fun desk toy but can power things with its integrated axle connection. You can print your own replacement flywheel and bolt it to the universal hub, or remove it entirely if you prefer. The engine doesn't require an engine stand; it's optional but adds a nice display feature. The hub has four 1.8mm holes in an 8x8mm square for M2 bolts. If connected to an air compressor, this engine produces decent torque at just 1psi (lung pressure) and is very strong when driven by high pressures. However, the problem with using an air compressor is it may not supply enough volume of air for this engine's needs; 30psi from the compressor might drop to 3psi by the time it reaches the engine. If you build this engine, I'd love to see a video or link to it! If you're interested in pushing its limits, I'd be fascinated to see what high pressures can handle.

With this file you will be able to print Working 4 Cylinder Air Engine Model with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Working 4 Cylinder Air Engine Model.