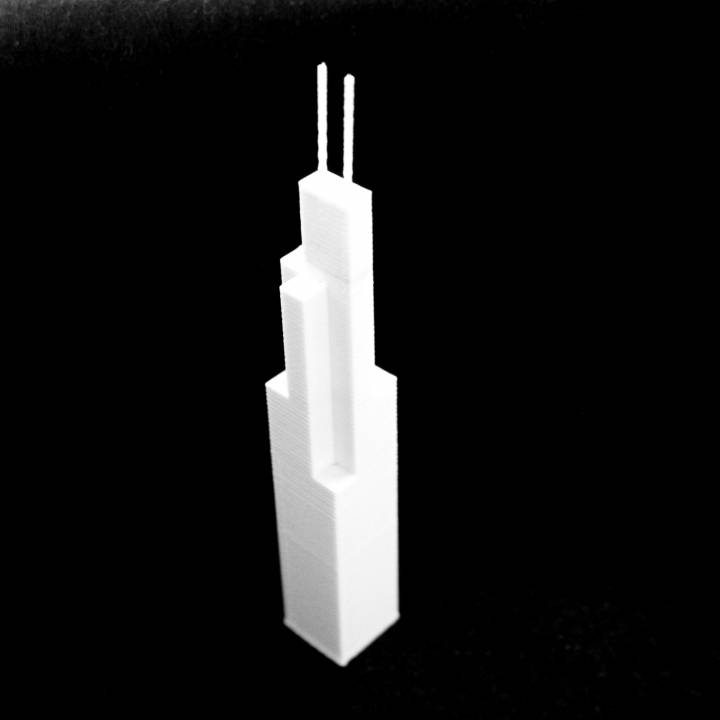

Willis Tower Spire in Chicago, Illinois

myminifactory

The Willis Tower, built as and still commonly referred to as Sears Tower, is a 108-story, 1,451-foot (442 m) skyscraper in Chicago, Illinois, United States. At completion in 1973, it surpassed the World Trade Centertowers in New York to become the tallest building in the world, a title it held for nearly 25 years. The Willis Tower is the second-tallest building in the United States and the 13th-tallest in the world. More than one million people visit its observation deck each year, making it one of Chicago's most popular tourist destinations. The structure was renamed in 2009 by the Willis Group as part of its lease on a portion of the tower's space. As of December 2013, the building's largest tenant is United Airlines, which moved its corporate headquarters from the United Building at 77 West Wacker Drive in 2012 and today occupies around 20 floors with its headquarters and operations center.In 1969, Sears, Roebuck & Co. was the largest retailer in the world, with about 350,000 employees. Sears executives decided to consolidate the thousands of employees in offices distributed throughout the Chicago area into one building on the western edge of Chicago's Loop. Sears asked its outside counsel, Arnstein, Gluck, Weitzenfeld & Minow (now known as Arnstein & Lehr, LLP) to suggest a location. The firm consulted with local and federal authorities and the applicable law, then offered Sears two options: an area known as Goose Island and a two-block area bounded by Franklin Street on the east, Jackson Boulevard on the south, Wacker Drive on the west and Adams Street on the north, with Quincy Street running through the middle from east to west. This latter site was decided upon, and preliminary inquiries determined that the necessary permits could be obtained and Quincy Street vacated. The next step was to acquire the property; a team of attorneys from the Arnstein law firm, headed by Andrew Adsit, began buying the property parcel by parcel. Sears purchased 15 old buildings from 100 owners and paid $2.7 million to the City of Chicago for the portion of Quincy Street that divided the property. Sears, which needed 3,000,000 square feet (280,000 m2) of office space for its planned consolidation and predicted that growth would require yet more, commissioned architects Skidmore, Owings & Merrill (SOM) to produce a structure to be one of the largest office buildings in the world. Their team of architect Bruce Graham and structural engineer Fazlur Rahman Khan designed the building as nine square "tubes" (each essentially a separate building), clustered in a 3×3 matrix forming a square base with 225-foot (69 m) sides. All nine tubes would rise up to the 50th floor of the building. At the 50th floor, the northwest and southeast tubes end, and the remaining seven continue up. At the 66th floor, the northeast and the southwest tubes end. At the 90th floor, the north, east, and south tubes end. The remaining west and center tubes continue up to the 108th floor.The Willis Tower was the first building to use Khan's bundled tube structure. This innovative design was structurally efficient and economic: at 1,450 feet, it provided more space and rose higher than the Empire State Building, yet cost much less per unit area. This structural system would prove highly influential in skyscraper construction. It has been used in mostsupertall buildings since then, including the world's tallest building, the Burj Khalifa. To honor Khan's contributions, the Structural Engineers Association of Illinois commissioned a sculpture of him for the lobby of the Willis Tower. Sears executives decided that the space they would immediately occupy should be efficiently designed to house their Merchandise Group, and that floor space for future growth would be rented out to smaller firms and businesses until Sears could retake it. The latter floor areas had to be designed to a smaller plate, with a high window-space to floor-space ratio, to be attractive and marketable to prospective lessees. Smaller floorplates required a taller structure to yield sufficient square footage. Skidmore architects proposed a tower with large 55,000-square-foot (5,100 m2) floors in the lower part of the building, and gradually tapered areas of floorplates in a series of setbacks, which would give the Sears Tower its distinctive look. As Sears continued to offer optimistic projections for growth, the tower's proposed floor count rapidly increased into the low hundreds, surpassing the height of New York's unfinished World Trade Center to become the world's tallest building. The height was restricted by a limit imposed by the Federal Aviation Administration (FAA) to protect air traffic. The financing of the tower was provided by the Sears company. It was topped with two antennas to permit local television and radio broadcasts. Sears and the City of Chicago approved the design, and the first steel was put in place in April 1971. The structure was completed in May 1973. The construction cost about US$150 million at the time, equivalent to $800 million in 2015. By comparison, Taipei 101, built in 2004 in Taiwan, cost around the equivalent of US$2.14 billion in 2014 dollars. Black bands appear on the tower around the 29th–32nd, 64th–65th, 88th–89th, and 104th–108th floors. These are louvres that allow ventilation for service equipment and obscure the structure's belt trusses. Even though regulations did not require a fire sprinkler system, the building was equipped with one from the beginning. There are around 40,000 sprinkler heads in the building, installed at a cost of $4 million. In February 1982, two television antennas were added to the structure, increasing its total height to 1,707 feet (520 m). The western antenna was later extended, bringing the overall height to 1,730 feet (527 m) on June 5, 2000 to improve reception of local NBC station WMAQ-TV. (Credit; Wikipedia) This object is part of "Scan The World". Scan the World is a non-profit initiative introduced by MyMiniFactory, through which we are creating a digital archive of fully 3D printable sculptures, artworks and landmarks from across the globe for the public to access for free. Scan the World is an open source, community effort, if you have interesting items around you and would like to contribute, email stw@myminifactory.com to find out how you can help.Scanned : Photogrammetry (Processed using Agisoft PhotoScan)

With this file you will be able to print Willis Tower Spire in Chicago, Illinois with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Willis Tower Spire in Chicago, Illinois.