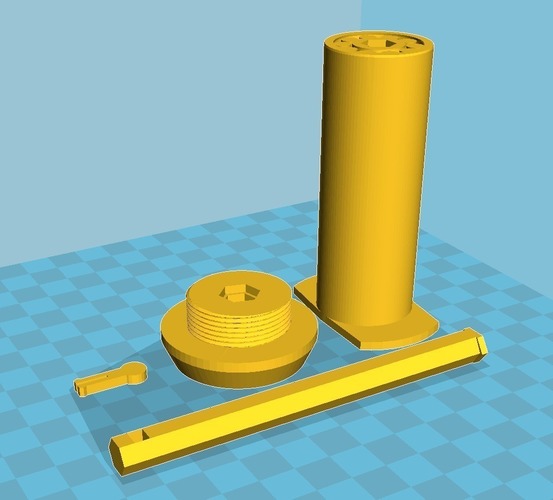

Wanhao Duplicator 6 Filament Spool Holder with printed bearings

pinshape

There are numerous Wanhao D6 (Monoprice Ultimate) printable spools available to replace the inadequate one that comes with the machine, but they all seem to require additional hardware like threaded rods, metal bearings, and nuts. This version features two printed bearings embedded inside the spool tube. You simply print, tap the spool gently, and twist to break free the bearing rods, and then install! Print Settings: Printer: Wanhao Duplicator 6 Rafts: Doesn't Matter Supports: Yes Resolution: .2mm Infill: 20-40% Notes: Prints fine at .2mm or smaller resolution. Specify the lightest type of support your slicer/printer can do. I printed this on PLA, and it has some tight tolerances, so I wouldn't suggest ABS or any other filament that shrinks. All objects in the stl file are aligned to the direction they should be printed. Be cautious when pulling off the pin object from the bed... it can be delicate. If you don't want to deal with the printed pin, you can use a paperclip or something else small instead. Post-Printing: The bearing rods and central column become "stuck" at the end of the print, and they need to be freed. 1) Insert the hexagonal shaft into the mounting bracket (the part with threads) so that the wider end will be on the inside of the printer. MAKE SURE WHEN YOU'RE DONE THAT THE HEAD IS FLUSH WITH THE THREADED MOUNTING BRACKET SURFACE. If not, the hexagonal tube may be protruding far enough into the printer to block the Z axis! 2) Release the exposed bearings on the main tube with a fingertip or a pencil or something, then insert the hexagonal shaft into the central shaft of the main tube on the side with the bearing rods. 3) WHACK the main tube gently to push the hexagonal shaft completely through. You don't need a hammer, but you need enough force to "break" free the central shaft and the internal bearings. 4) Put the pin in the end of the hexagonal shaft to keep it from sliding off during use. 5) Spin the bearing tube by hand. It'll be stiff at first, but once it breaks in, it'll spin really well. Making Of: As anyone with a d6 can tell you, the spool is too short, and it can cause gaps in prints because the extruder has to work hard to drag filament off a spool that's rubbing against the back of the machine. I took an existing model of the spool for the threaded base, used an OpenSCAD script to create custom bearings, and put them inside the main tube. Instead of a threaded rod and nut, I put an enlarged nut head on one end of a hexagonal rod, and a hole for a pin on the other (and added a printable pin).

With this file you will be able to print Wanhao Duplicator 6 Filament Spool Holder with printed bearings with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Wanhao Duplicator 6 Filament Spool Holder with printed bearings.