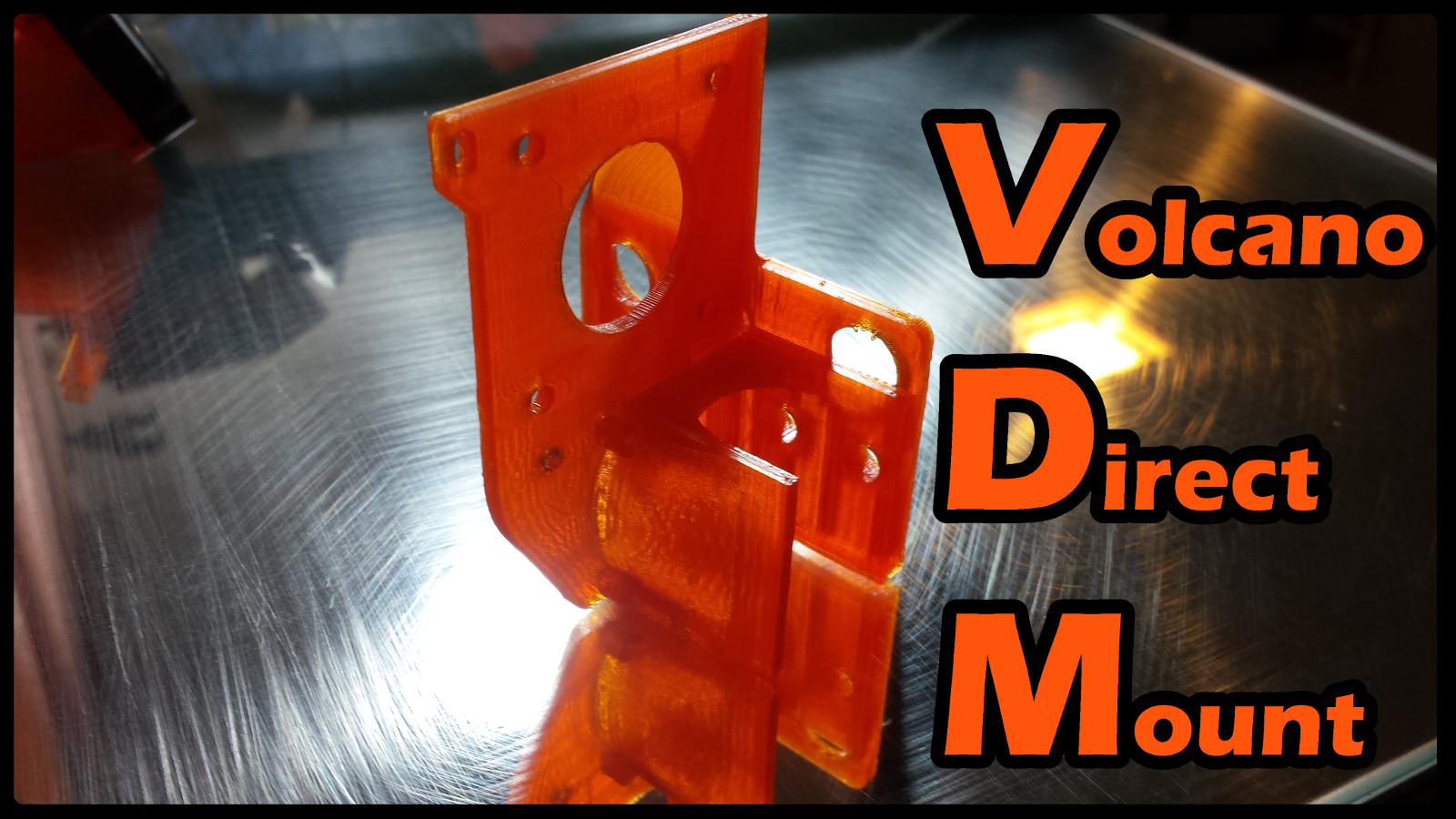

Volcano Direct Mount for CR-10 Printer

myminifactory

These parts are designed to mount an E3D Titan with pancake stepper motor, v6 heat sink, and volcano hot end on the CR-10 family of printers. Once assembled and mounted, this will place the nozzle in the same position as the original hot end. It is designed to go onto the carriage, taking up as little space as possible, so that no printing space is lost in any axis. The parts for my build were ordered from AliExpress (Trianglelab) and can be seen in one of the stock pictures, except that I swapped the hot end with a volcano. You can choose to use either a 40mm fan or an 80mm fan, or add a part cooling fan of your design. In addition to the titan, v6, volcano, and other associated parts, you will need either four 1mm M3 and three 1.2mm M3 socket head screws, or seven 1.2mm M3 socket head screws. Step 1: Remove the stock housing and hot end from the carriage. Place them aside and keep all the screws together to be able to re-use this part in the future. Step 2: The pegs used to attach the stock heat sink are used as locator/support pegs with the mount, but will not be screwed in. Check now that those pegs fit in the matching two holes of the mount. If your printer made the holes a bit too small, which is common, simply enlarge the holes very slightly with a 7/32 drill bit. Don't go fast and let the bit do the work. Step 3: Use four screws (1 or 1.2mm, depending on the fan) to mount your part cooling fan to the funnel (either 40mm or 80mm). Screw directly into the plastic, which will squeak as you do it but will hold nicely. Step 4: Use one 1.2 mm screw to attach the part cooling funnel to the mount. Again, screw directly into the plastic. Don't make it too tight at this point. Step 5: Attach the stepper motor, titan, and v6 heat sink to the mount using the supplied hardware and following the instructions found here: https://wiki.e3d-online.com/wiki/Titan_Assembly Step 6: Attach the mount to the carriage by slipping it onto the pegs. Use two 1.2mm M3 socket head screws to secure the mount to the carriage by the holes used to mount the stock metal housing. Note that one screw is recessed into the mount and will stick out the back more - this is normal. Step 7: Attach the 30mm heat sink fan to the mount using the supplied screws. Three holes are provided in the mount, but I just used the top left and bottom right ones. Pointing the part cooling fan: With the 40mm fan, there's little adjustment to be done, but with the 80mm fan, you need to get the right angle. In both cases, lower your newly attached assembly to the print surface (make sure your printer is off when you do this) and adjust the fan so that the tip is a mm or two off the print surface. Once there, you can tighten down the fan funnel mounting screw used in step 4. Getting it connected: Once all attached, you will still need to wire up the new parts to your printer. There are many options available, so I'll leave you to use the one you like best. I chose to cut the stock cable halfway to the controller box and put in an 8-pin Molex connector. This way, I can swap this VDM print head or the original print head by turning a few screws and plugging in the new one. Stepper motor: You'll need to connect the pancake stepper motor to the controller box as well. I made a connector that the original cable plugs into so that I just unplug the original extruder motor and plug in the new one. Read up on four-wire stepper motors and polarity when doing this, so you do it right. At time of writing, I'm still running the stock firmware on my CR-10, so I cannot permanently update it on the controller. Instead, I added this line to my start G-code in my slicer: M92 E418; set steps per mm of extruder to 418. About the design: I designed this to allow me to do large prints rapidly, which requires extruding a large volume of plastic quickly, with no snags in the filament, and with plenty of cooling. Because some of these prints will be done in TPE and TPU, a direct drive solution seemed appropriate. Also, the design of the titan, used in this way, makes it very quick to switch between 1.75mm and 3mm filament, another requirement when pushing out lots of plastic quickly.

With this file you will be able to print Volcano Direct Mount for CR-10 Printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Volcano Direct Mount for CR-10 Printer.