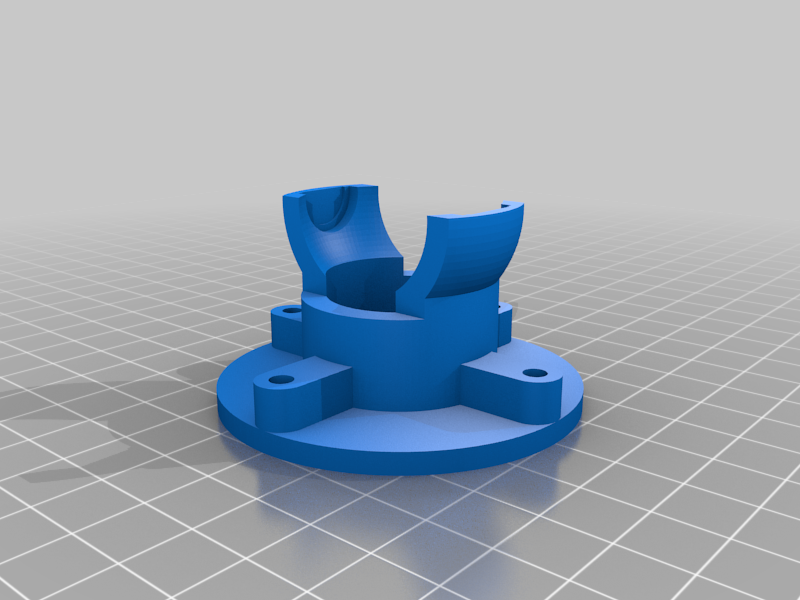

V2.0 Thrustmaster Warthog replacement gimbal

thingiverse

Please Read!\r\nV2.0 of the gimbal is designed to address issues with calibration and strength, but it's a bit more challenging to assemble than previous versions. One notable change is that the stock sensor mount is reused, but it requires modification to fit properly. Unfortunately, this is a one-way modification, so I'm working on sourcing a second base for good pictures of the process. Until then, my prototype modification will have to do.\r\n\r\nInstructions Follow!\r\nMy Thrustmaster Warthog base wore down over time and developed significant play in the gimbal. This set of STL files replaces the stock gimbal with one that utilizes Tamiya 1280 bearings, easily obtainable from hobby stores.\r\n\r\nBearing Dimensions:\r\nOuter Diameter: 12.0 mm\r\nBore: 8.0 mm\r\nWidth: 3.5 mm\r\n\r\nNo additional parts are required beyond those in the joystick base.\r\nIf desired, a 3D printable replacement sensor mount has been kindly provided by Nopileus to avoid modifying your stock one.\r\nhttps://www.prusaprinters.org/prints/44613-thrustmaster-warthog-joystick-sensor-holder-for-be\r\n\r\nSteps to Build:\r\n1. Install the printed "stick holder" into the stock grip bell, ensuring the rounded edge fits snugly. Be cautious not to damage wires by aligning the wiring notch on the stick holder with the wire side.\r\n2. Install two bearings onto the printed "inner gimbal" on the thicker edges. The thinner pair of edges should be aligned for a full 40 degrees of roll axis.\r\n3. Insert the inner gimbal assembly into the stick holder, aligning bearings with slots in the stick holder that accept them. This may require significant pressure to fully install.\r\n4. Ensure the stick holder is fully inserted and as centered as possible due to the bell's shape. Check for even depth on both sides by looking for any discrepancies.\r\n5. Install the original grey sensor assembly into the printed "outer gimbal." It might be a tight fit, but it will go in.\r\n6. File down the original grey plastic of the sensor assembly to create clearance for the new mechanism. File it flush with the outer gimbal assembly.\r\n7. Install the remaining two bearings onto the inner gimbal posts.\r\n8. Pass grip wires through the inner void in the outer gimbal and out the bottom.\r\n9. Align the inner gimbal and outer gimbal so that free bearings fit into slots in the outer gimbal. This may require significant pressure to fully install.\r\n10. Verify that grip wiring is still free to move. If not, try to determine where it's stuck and adjust accordingly.\r\n11. Confirm that the DIN socket's key is on the left side looking from the top, that grip wiring is on the left side, and that the outer gimbal's base has the leg with two holes on the left side.\r\n12. Set the assembly onto the original metal base plate with the USB lead hole facing forwards.\r\n13. Invert the assembly and screw in the original forward and rear screws.\r\n14. Reassemble the control logic board, re-solder the earth lead, and then screw in the remaining original screws over ground ring connectors. Alternatively, you can create a new earth lead by soldering a new wire on and attaching a ring connector.\r\n15. Reassemble all other elements.\r\n\r\nCalibration will be required via the Thrustmaster Joystick Calibration tool (current version 1.13), which can be found on Reddit or the Eagle Dynamics forums.\r\nDon't forget to disable hardware dead zone in TARGET before calibrating in Windows.

With this file you will be able to print V2.0 Thrustmaster Warthog replacement gimbal with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on V2.0 Thrustmaster Warthog replacement gimbal.