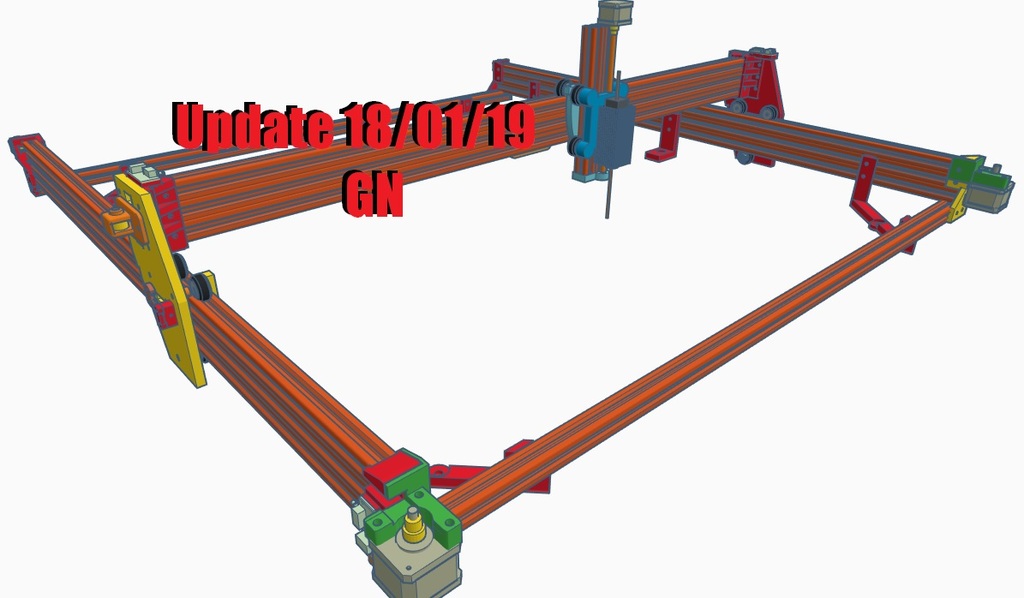

V-slot Laser,CNC, frame with internal belt.

thingiverse

Hi! Take a look at my other designs on Thingiverse: https://www.thingiverse.com/BuiltBrokenGlued/designs **Update 26/03/2019** I'm currently working on a new project that will include all the necessary files for download. As it stands, I'm not releasing the files just yet due to the ongoing nature of this work in progress and some parts not being entirely my own (see below). **Please use the designs pictured as reference or inspiration for your own projects** **Update 18/01/2019** Check out Design 4 Offset X axis.stl Sections of the design have undergone changes after printing individual components, which revealed flaws or inspired better ideas. The core concept remains the same, but with adjustments to make more efficient use of bed space. The X bracket has been offset to the rear to take full advantage of the available area. I've also created a mockup for a Z axis designed specifically for laser engraving in Tinkercad. Additionally, the Y axis runner has been relocated outside to preserve the build area's cleanliness and allow the X axis complete travel. All parts are now original designs except for the Stepper motor sample at https://www.thingiverse.com/thing:1735915 The printed images feature M5 x16mm button socket with temporary spacers; these will be replaced with M5 x 8mm stainless once construction is complete. **Original** I've drawn inspiration from other Thingiverse projects to create this framework according to my vision. Some parts in the photos are still utilizing original components, though modified. *X belt tensioner in pink* *Frame corner mounts in brown* This frame utilizes **V-slot** 1000mm/1mtr 20x20 Aluminium extrusion and 1000mm/1mtr 20x40. The 20x40 is used for the X & Y axis runner, while the 20x20 serves as supports for the X axis. Utilizing V-slot rubber bearings from Banggood, there will be three wheels per mount that can be adjusted using Eccentric Spacers to achieve optimal tension on the 2040 extrusion. The green Y axis running mounts are identical on both ends and feature a separate module that can be attached for prototyping stepper and idler mounts. This will remain modular in the final design. I may develop two different frame corner designs, keeping them modular as well. However, the Y axis idler doesn't require the same level of strength as the Y axis stepper mount. The belt runs through extrusion, accessible through holes at either end of the X & Y axis. The belt is secured and tension adjusted on the Y axis mount plate shown in orange/red. Tension adjustment utilizes a hidden M3 allen head screw within the sliding adjuster; however, there's currently no support for this component due to the belt's tension holding it in place. This aspect may be revised once prototypes are developed. I haven't designed the Z axis yet, but I plan to use the 450nm 5W Laser Engraving Module with a focus ring. This will allow the laser to move down as it cuts through thicker materials, maintaining focus throughout the process. *I'd like to incorporate a small CNC attachment into this frame, though I haven't explored this aspect yet.* The electronics are still a work in progress. I haven't decided on software but have ordered a RAMPS 1.4 + Arduino Mega 2560 for this project. This setup can run the Z axis if needed or two separate steppers for the Y axis instead of sharing one DRV driver between both steppers. *The heated bed is not part of this project; it was included in the kit as a great deal compared to other Ramps kits available.* I've ordered all necessary parts except for the Stepper motors and Extrusion.

With this file you will be able to print V-slot Laser,CNC, frame with internal belt. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on V-slot Laser,CNC, frame with internal belt..