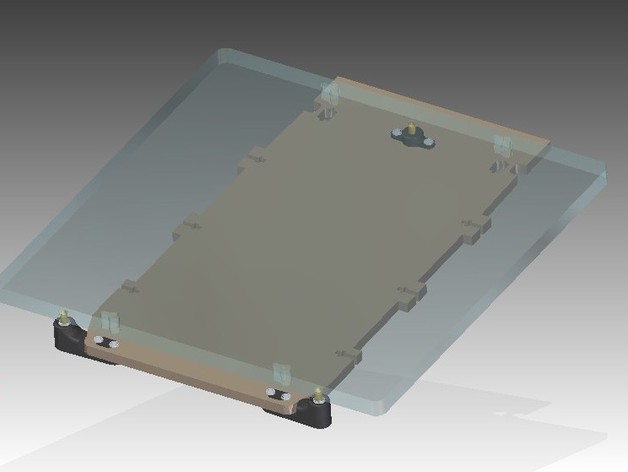

Ultimaker buildplate 3 point levelling

thingiverse

To achieve a 3-point bed levelling with zero force platform release, follow these instructions. Drill a 4mm hole in the z-stage base plate's center, aligning it with the original cutouts' centers. Then, drill two 3mm holes at 10mm left and right from the 4mm center hole. Counterbore five millimeter tapped blind holes, 2mm deep, into the acrylic buildplate, one centered at the rear and another at +/-80mm from the plate's center. Use the tick's end to place these holes correctly. The hole's cone-shaped bottom must match the supporting headless screw's tip precisely. Finally, move the print head to the front left and right corners and adjust the platform height using the Ultimaker tool screwdriver. Lastly, adjust the rear center screw. You will need six M3 x 10 screws, six M3 nuts, three M4 self-locking nuts, and three M4 x 10 headless screws for this procedure.

With this file you will be able to print Ultimaker buildplate 3 point levelling with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ultimaker buildplate 3 point levelling.