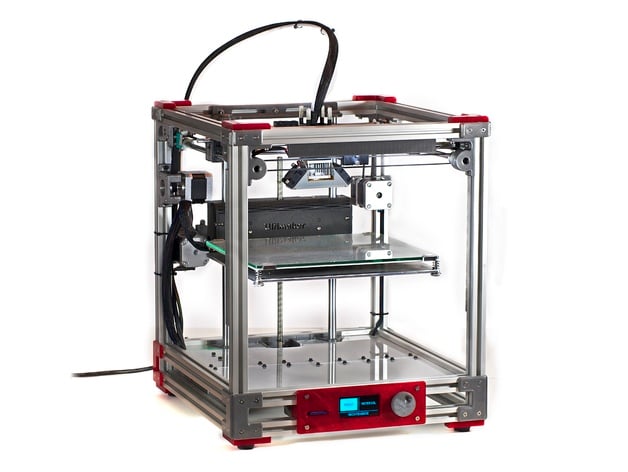

Ultimaker 2 Aluminum Extrusion 3D printer

thingiverse

This is not The Greatest UM2 Clone, no. This project began as a fun way to learn AutoDesk Fusion 360 and create a tribute to the original. I started by importing the entire Solidworks CAD file into a new Fusion 360 project and dropping the frame from the printer. Then, I built 20x20 Misumi aluminum extrusions to wrap the printer guts and worked on building brackets to support all parts that previously attached to the frame. I've been printing nonstop on this new printer with precision and quality identical to my real UM2. In fact, I can use the same GCODE in either machine with consistent results. Fusion 360 Source Download Link - Use this link to download a copy of the source in your CAD flavor. Buying Parts The BOM Click here Prices in the BOM are outdated; find parts by following the links in the BOM. I had positive experiences with sellers and found parts identical or very close to official UM2 parts, including the 1.75mm version nozzle/heatblock. I used the BOM for building either the Z-axis platform/heated bed or purchasing the official UM2 heated bed kit (intended for the UMO+). This costs only $15 more when accounting for the PSU and lead screw Z-axis motor. There's a small electronics board, acting as a relay to power the heaterboard with 24V and output 19V for the UMO. It's optional but offers value in future projects. Building either option requires patience; if you're adventurous, choose the kit. Build Instructions Build Instructions - Click here Please follow official Ultimaker 2 assembly instructions for assembling the gantry and print head. My printer uses a frosted 1/4" acrylic floor cut from a single sheet, except it needed to be in two parts. This was because my laser cutter is slightly too small, and I sanded the underside of the parts after assembly. To maintain alignment with other parts, I used CorelDraw to create a template that allows you to easily make adjustments if your acrylic sheets come out slightly askew like mine did. Update 1 Updated Gantry parts by increasing tolerances for improved bearing fitment. From another build, it's found bearings required an extra .1mm space. Updated Y-Axis motor mount for increased room and the belt, which now fits properly on all axes in all directions (and works very nicely!). Similarly to a previous project I shared, the original files no longer are maintained in this thread due to file duplication and redundancy from previous builds, so instead they are available by using this link: The Original files have all had the "_v2" prefix appended. If your parts fit too well it's likely they needed some tolerancing tweaks (and this also means it should be even more precise, nice). Files deprecated in v1 can still be found by clicking here

With this file you will be able to print Ultimaker 2 Aluminum Extrusion 3D printer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Ultimaker 2 Aluminum Extrusion 3D printer.