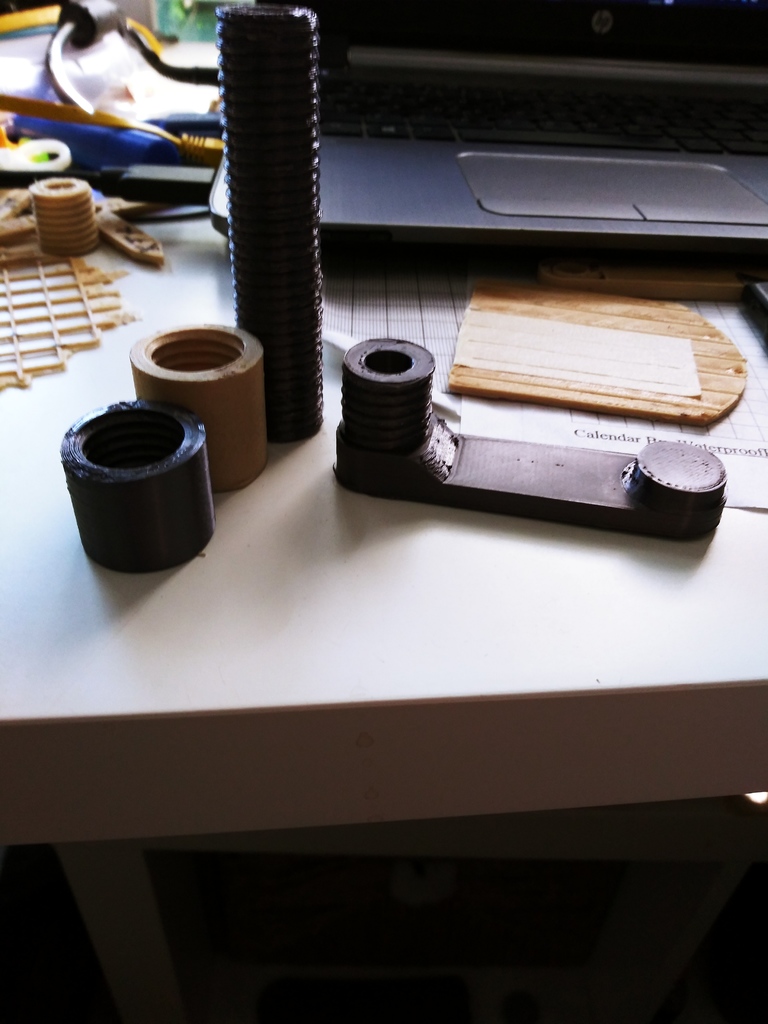

Tube and Rod clamp

thingiverse

I needed a custom clamp, so I sat down and after sixty minutes, I had this design complete. I started with a 120mm Ø bounding box, which matches my mini delta print bed with a glass plate. As I was printing, I expanded on it. The first clamp part broke at 25% completion, so I switched from grid 25% to gyroid 35%, added three walls instead of two, and included some chamfers and a round clamp pad at the end. While I was there, I adjusted and created version 2 of an 80mm threaded rod, as well as a tool to torque it down. I print tall tubes and rods with a raft. The wood PLA kept causing jamming issues, so I switched to silk black. I added three different clamp ends: internal, external threaded, and no threads. Threaded rods are 80mm long, and the threaded tube is 100mm (currently printing). Use your slicer to make them smaller if you need; in Cura, simply move the part below the print bed surface by the desired amount, and it should still work. You'll need two clamp ends, at least two of the 25mm tubes, or a combination of 25mm and 100mm. Along with a threaded rod, print as many as you need for your specific requirements. My special needs would have required two clamp ends, two 25mm tubes, one 80mm threaded rod, and one 100mm threaded tube - although I haven't had the chance to test them yet, as they're still printing. With the wood PLA jamming and one part breaking (the clamp v1 broke after a 120-minute print job), using two 25mm tubes, a threaded tube, rod, version 2 of the clamp, and any other desired clamp style will take around 13 hours to print, assuming you're speeding up your machine via firmware to sometimes 200mm/sec. I also had ironing turned on during this process. (Estimated print time for internal threaded clamps and no threads with ironing is 103 minutes and 57 minutes, respectively.) The tubes are hollow, but the threaded rods are as well. This design is marked "work in progress," as I may still make two changes: removing version 2 of the treaded rod since it snaps too easily (although those can still be used), adding a hex to hex shank, and possibly creating a new version of the tool and making a version 3 of the threaded rod. I might also change the holes in the rods to hex for using a tool to remove stuck items - after all, PLA is prone to jamming.

With this file you will be able to print Tube and Rod clamp with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Tube and Rod clamp.