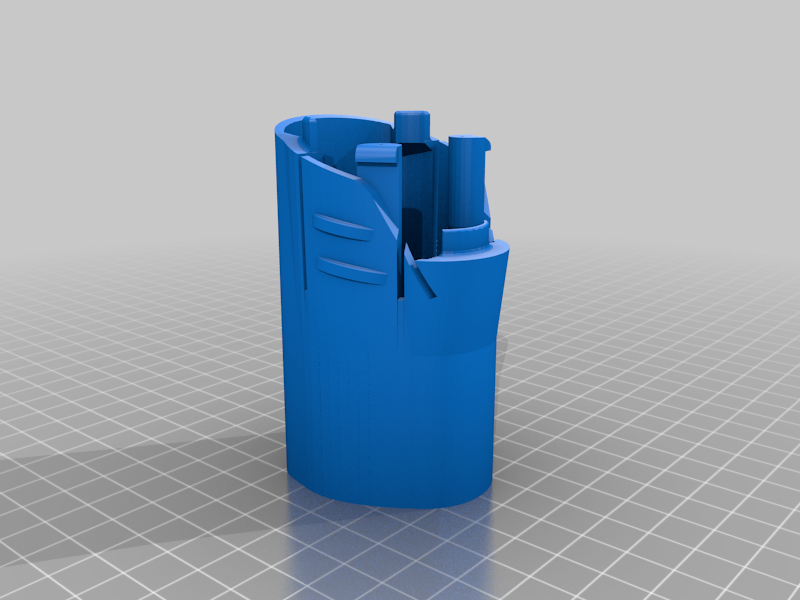

TS100 Milwaukee M12 battery adapter case

thingiverse

An adapter to use a M18 Milwaukee battery with a TS100 solder iron and enclose all the bits when not in use. The battery socket section is based on a design by ksuszka. Printing: PETG has been tested and is preferred over PLA. Printed with PETG at 230c 30mm/s using 0.5mm nozzle. If you are using a different size nozzle adjust wall thickness to closest multiple of your nozzle. Base socket - Supports required. Some areas may not need depending on your overhang printing ability. I would recommend floor only. 1.5mm walls. 15% infill. Top cap - Supports not needed. 2.0mm wall for strong clip tabs. 15% infill. The tabs have a hole inside the clip arms to induce solid filling at 2.0mm wall thickness. Bottom cap - nothing special required here. Parts needed: Small rocker switch 20x15x25 Spade connectors male Barrel connector suitable for TS100 (ideally 90 degree but not needed) Wires Assembly: Test fit the barrel connector and solder it before installing it into the base and verify where it should side in order to engage into the solder iron. Use hot glue to secure the barrel connector in the base and before the glue is totally set, insert the iron into place in order to align it before the glue sets. The switch, spades, and barrel are appropriately wired and the bottom cap can be threaded on. Solder the spade terminals to their wires. Inserting a battery into the dock can help in aligning to spade terminals. Heating the spade terminals may help in inserting them to the required depth but be cautious not to short the battery once the terminals make connection to the battery. Adjusting the locking tabs with hot air can provide for more positive engagement if required.

With this file you will be able to print TS100 Milwaukee M12 battery adapter case with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on TS100 Milwaukee M12 battery adapter case.