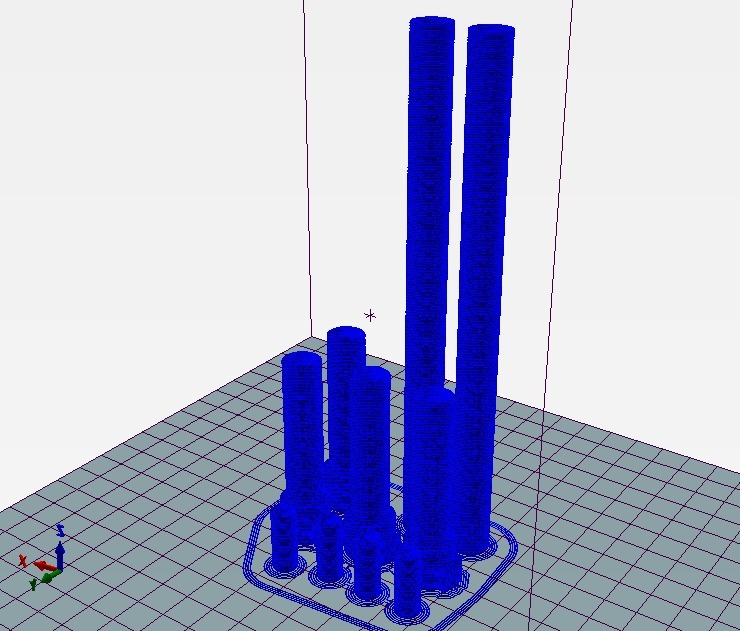

TronXY P802MA Modular frame braces

thingiverse

I fabricated some modular vertical frame braces to minimize wobble in the z-x plane to less than 0.1mm relative movement at the top of the z axis. Note that this was crudely measured. At this stability, it is an angular error of 0.026 degrees and the deviation in mm in the plane vertical alignment equals: the z axis printing height x 0.000454. The multiplier originates from the tangent of the angular error. The braces fit together with dowels that are friction fit. They fit between the horizontal surfaces of the acrylic frame. There is some movement along the rod, you can try different infill patterns or increase the diameter to gain more rigidity but ensure they don't obstruct the carriages or anything else. Scad files are included for customization. You require two frame braces and two dowels and one rod for each side. It might be easier to print two sets of the above all together so you have a complete brace for each side. If you need to make slight adjustments, you can print a washer to place between the brace sections and the rod. If the dowels are tight, don't force them, lightly sand them. A friction fit doesn't matter much here as the part is in compression. Don't bend the rods sideways or they will break! You might experiment with a different cross-section to achieve more rigid rods. This is left as an exercise for the reader. Actually, the braces can be printed alone and the rod replaced with copper pipe or tubing 15mm outside diameter (OD). The base of the brace is 16mm OD and the shaft is 12mm OD. Copper pipe is very strong and rigid and cheap. Again, fine adjustments can be made with a 0.2mm high printed washer at the base of the pipe. You might have a piece laying around.

With this file you will be able to print TronXY P802MA Modular frame braces with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on TronXY P802MA Modular frame braces.