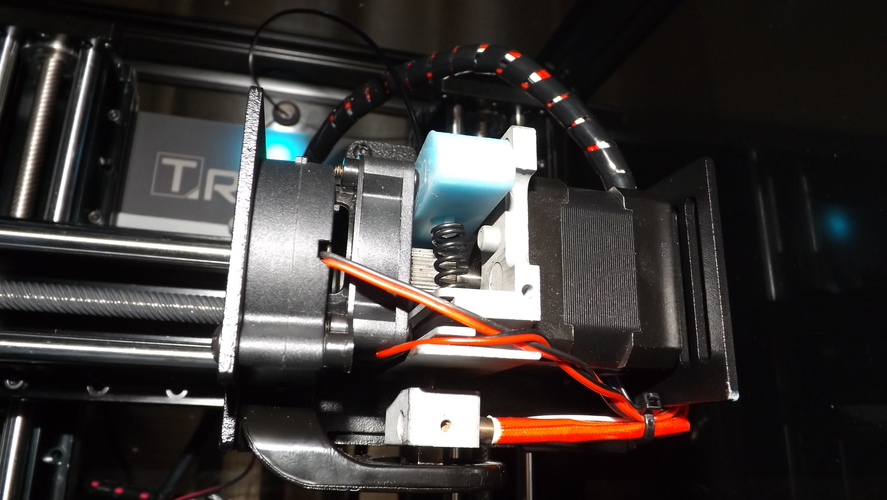

Trinus Extruder Arm

pinshape

After countless hours of printing on the Trinus, the extruder quick release arm failed catastrophically, prompting me to design a replacement. This new part utilizes the bearing and screws from the original, eliminating the need for any additional components. Design Process: A broken piece was carefully scanned using a flatbed printer/scanner, and then imported into Fusion360 where it was traced and extruded. The scan was scaled to its correct dimensions before sketching and extruding text onto the design. Once complete, the file was exported and printed in ABS. Print Settings: Printer: Wanhao Duplicator i3 V2 Rafts: No rafts were used. Supports: Yes, supports were employed to ensure a successful print. Resolution: A resolution of 0.2mm was selected for optimal detail. Infill: The infill density was set at 40% to balance strength and weight. Material: ABS was the chosen material for its durability and versatility.

With this file you will be able to print Trinus Extruder Arm with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Trinus Extruder Arm.