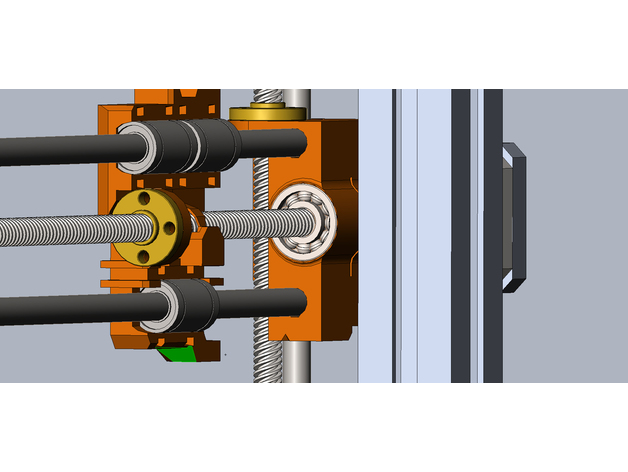

Trapezoidal leads screw in the 3D printer, solution of axial backlash

thingiverse

Features: Using the leads screw in raw unmodified form Only two radial bearings and two axial bearings per axis The price is up to $15 per axis Solutions for using trapezoidal leads screws in the Y axis with a 3D printer are available. The proposal is optimized for AL profiles 30x30mm. The problem of springing belts and their drawbacks can be solved by using a trapezoidal screw. Speeds can then be matched by using 24V for step motors, which can then be run at higher speeds with the same torque as on 12V systems. Here, it is necessary to solve axial backlash in receiving a bolt and axial backlash nut on the screw. The nut can be used Anti-Backlash Nut, available here: http://tinyurl.com/zmrng67. For lead screws, angular contact bearings are commonly used, which eliminate backlash. However, it is necessary to have machined ends of the screw, often difficult and challenging, and cannot be done at home. This solution allows the use of leads screws in raw unmodified form. It requires 2 pieces of 608 radial bearings, 1 piece axial bearing F4-10, and 1 piece axial bearing F6-12. The entire solution can fit up to $15 USD, including the lead screw and nut. Because this solution cannot use flexible couplings, but must be used rigid couplings, see here: http://tinyurl.com/jmrjdzy. Everything is assembled such that the loose coupling on the motor shaft is eliminated by tightening at least two screws. Axial backlash is then eliminated with a Bolt Pretensioner at the end. The engine is tightened by the coupling on the motor shaft, and then loosened. After rotation of the screw, it is again tightened by all four screws. Axial backlash is now 0.0 mm. Update January 23, 2017: MotorHolder for Lead Screw exactly 300 mm Update October 10, 2017: Solution for X-axis Lead Screw 365 mm length AL profile 30x30mm sizes: 3 pieces of X axis 320mm 2 pieces of Y axis 320mm 2 pieces of Z axis 360mm Radial bearings 608 - 4 pieces Axial bearings F4-10 - 2 pieces Axial bearings F6-12 - 2 pieces Lead Screw & nut anti-backlash X axis 365mm - 1 piece Lead Screw & nut anti-backlash Y axis 300mm - 1 piece Lead Screw & nut anti-backlash Z axis 300mm - 2 pieces The X carriage is modified from Prusa I3 MK2 to screw version, available here: http://www.prusa3d.com/prusa-i3-printable-parts/. The assembly procedure and definition of backlash are similar to the Y axis. Tightening the clutch on the engine shaft is made from behind the hole on the engine bracket. More details and possible queries can be sent via email or comments.

With this file you will be able to print Trapezoidal leads screw in the 3D printer, solution of axial backlash with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Trapezoidal leads screw in the 3D printer, solution of axial backlash.