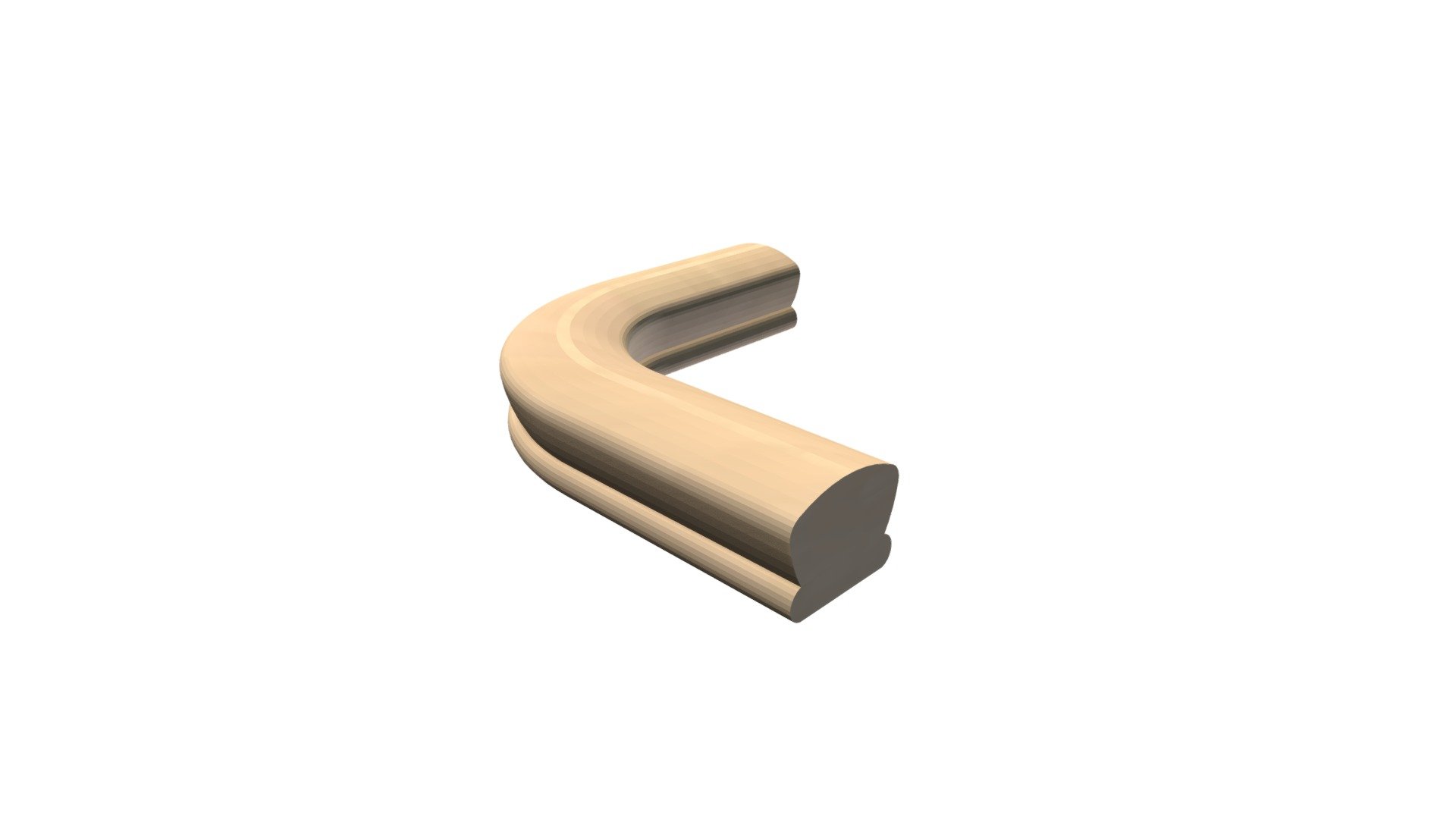

Traditional Profile Joinery Part - Level Turn

sketchfab

Joining two pieces of wood together requires a strong connection that will withstand the forces of gravity and time. One effective method is traditional profile joinery, where two turned parts are fitted together to create a robust joint. The first step in this process involves creating two identical profiles, which can be done using a lathe or by hand. The profiles should be carefully crafted to fit snugly together, with precise measurements to ensure a secure connection. Once the profiles are complete, they are cut to length and prepared for assembly. This may involve sanding or machining the edges to create a smooth surface for joining. The next step involves applying wood glue to the joint, making sure to fill any gaps between the two parts. The joint is then pressed together firmly, using clamps or other tools to ensure a tight bond. As the glue dries, the joint becomes stronger and more rigid, providing a solid foundation for the rest of the project. With patience and attention to detail, traditional profile joinery can produce joints that are both beautiful and durable. The final result is a strong and stable connection between two pieces of wood, perfect for building furniture or other woodworking projects. By mastering this technique, woodworkers can create joints that will last for generations.

With this file you will be able to print Traditional Profile Joinery Part - Level Turn with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Traditional Profile Joinery Part - Level Turn.