Torque measurement

thingiverse

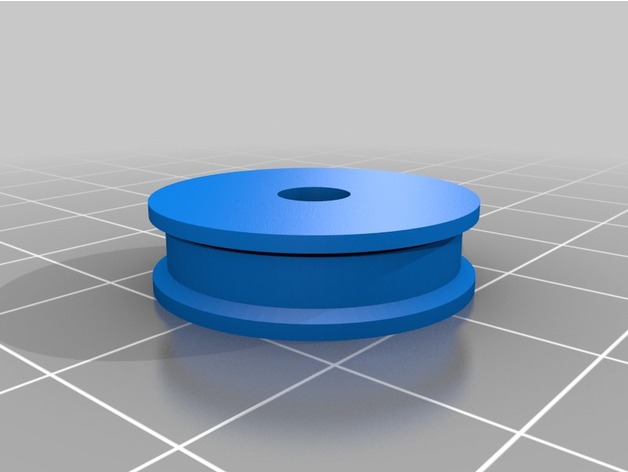

As I didn't see any published results here, let me walk you through how I measured the torque requirements and what the motors are capable of delivering. The ID is 5mm, a standard dimension for Nema17 motors and extruder shafts. Use a flat M3 grub screw, drill to 2.5mm without tapping. I added a steel shim, but it's not strictly necessary. Drill a 1mm hole in the flange, thread in about 20cm of spectra or fishing line from inside the pulley, then tie a knot. Create a loop for the scale at the free end. As for its use, the picture is self-explanatory: for motors, it winds up the thread; for other measurements, wind up some turns and pull. The pulley has a 2cm diameter, so what you read on the scale is the torque in kgf.cm multiplied by g if you're being precise or simply by 10 to get it in N.cm. Now you can measure the torque needed to move your table, gantry, extruder, etc., and compare it with what your motor can deliver. Adjust its current accordingly. Keep in mind that this is a static measurement; be cautious when adjusting your motor's current.

With this file you will be able to print Torque measurement with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Torque measurement.