Tolerance Test

thingiverse

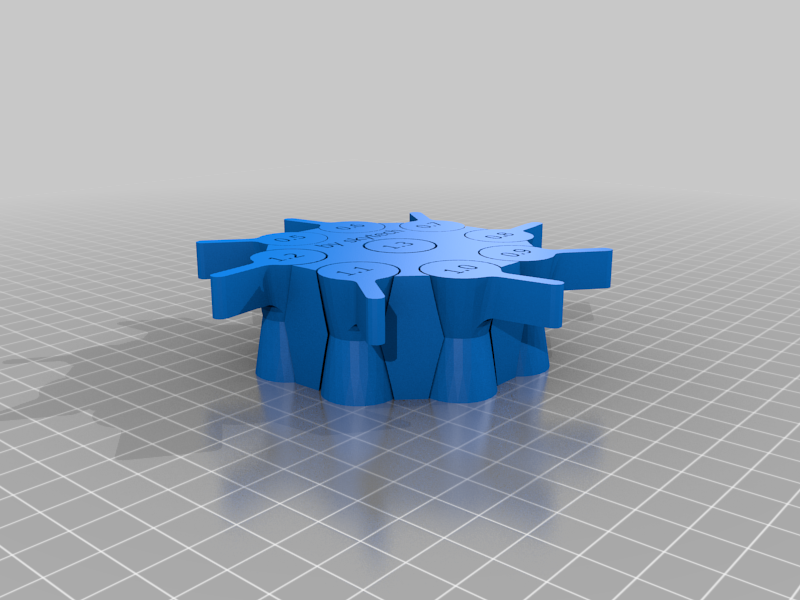

A 3D printer tolerance test is a crucial step in assessing the accuracy and precision of a 3D printer's output. It involves printing a designated model with specific dimensions and examining the resulting object for any variations or deviations from the intended design. Let's explore a popular example, the 70 mm octagon tolerance test, which comes in two versions: the rough tolerance test and the fine tolerance test. The rough tolerance test serves as an initial assessment, providing a quick evaluation of the printer's capabilities. It involves printing a 70 mm octagon with predefined specifications and examining the finished model for any visible discrepancies. These discrepancies can include variations in the dimensions, such as the length of the sides or the angles between them. The rough tolerance test helps identify potential issues with the printer's overall accuracy and provides a general idea of its capabilities. On the other hand, the fine tolerance test is a more detailed examination of the printer's precision and consistency. It involves printing a 70 mm octagon with much tighter tolerances, aiming for a higher level of accuracy. The fine tolerance test is designed to reveal any subtle variations in the dimensions, ensuring that the printer can produce precise and uniform results. It requires meticulous examination of the printed model using measuring tools to assess if the dimensions align with the intended design. During both tests, several important factors need to be considered to ensure accurate results. These factors include: 1.Bed leveling: Proper calibration and alignment of the printer's print bed is crucial to achieving accurate prints. Uneven bed leveling can lead to inconsistencies in the model's dimensions. 2.Filament quality: The type and quality of the filament used in the printing process can significantly impact the final results. Different filaments have varying shrinkage rates, which can affect dimensional accuracy. 3.Printer settings: Adjusting the printer settings, such as print speed, layer height, and extrusion temperature, can influence the precision and quality of the printed model. Fine-tuning these settings is necessary to achieve optimal results. 4.Cooling: Adequate cooling of the printed layers is essential to prevent warping and ensure dimensional accuracy. Insufficient cooling can lead to deformities in the model. By conducting a 3D printer tolerance test, both rough and fine, users can gain valuable insights into the capabilities of their printer. It allows them to identify any areas for improvement, make necessary adjustments, and achieve higher-quality prints with greater accuracy.

With this file you will be able to print Tolerance Test with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Tolerance Test.