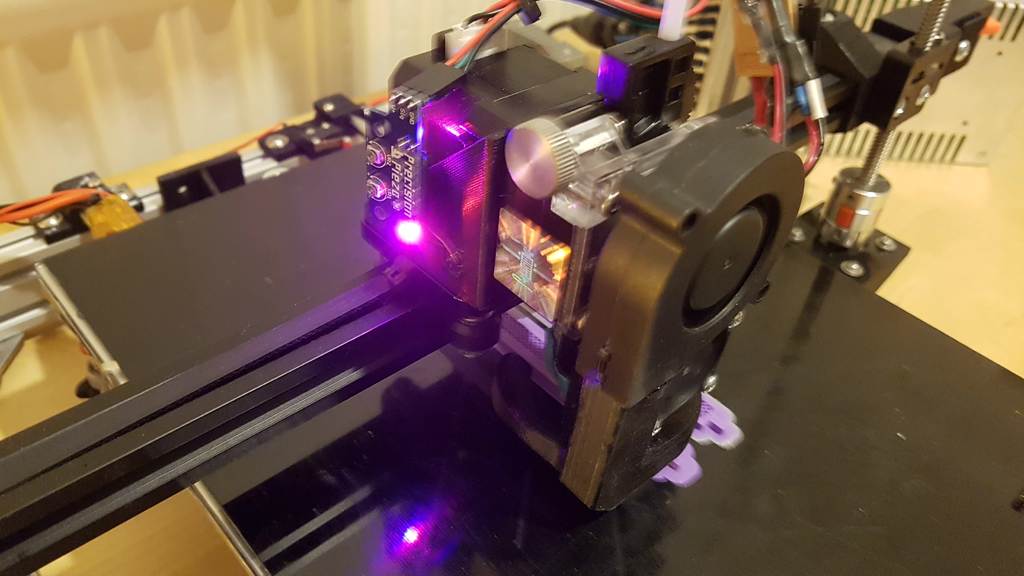

Titan X-carriage with piezo Z-probe

thingiverse

A modified version of DJDemonD's titan + piezo mount, designed specifically for an open-build mini-gantry setup. The mounting system relies on three holes to secure it firmly in place. I incorporated a groove and hole into the design to route the piezo connector out safely, along with a stud to attach the Precision Piezo PCB directly onto the mount. Similar to the original, a small amount of superglue applied to both ends is enough to hold the piezo and encourage its flexing motion in sync with the mount's movement. The result is seamless performance - my probes now achieve a typical SD-from-mean reduction of half, and nearly eliminate vibration artefacts altogether due to the nozzle's significantly closer proximity to the pivot point. I constructed this piece using PLA with 100% infill to ensure sufficient stiffness for eliminating the unwanted vibrations I was experiencing with my x-carriage. Notably, even though I opted for a relatively stiff material, the flex remains more than adequate for generating an effective signal from the piezo, so redoing it in PETG doesn't seem necessary at this point. As an added precaution, I printed a second unit to keep on hand; if fractures do occur in the future, switching out the piece will be a quick and straightforward process. To ensure proper printing of the flexing slots, I found it essential to print the mount upright. To accommodate the holes in the vertical walls and under the screw post, I used "supports everywhere" at 55° in Cura. While I may revisit this design with a fillet running up to the post in the future, for now, it's not an absolute necessity.

With this file you will be able to print Titan X-carriage with piezo Z-probe with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Titan X-carriage with piezo Z-probe.