Titan Extruder for the Anycubic I3 Mega, Prusa i3

thingiverse

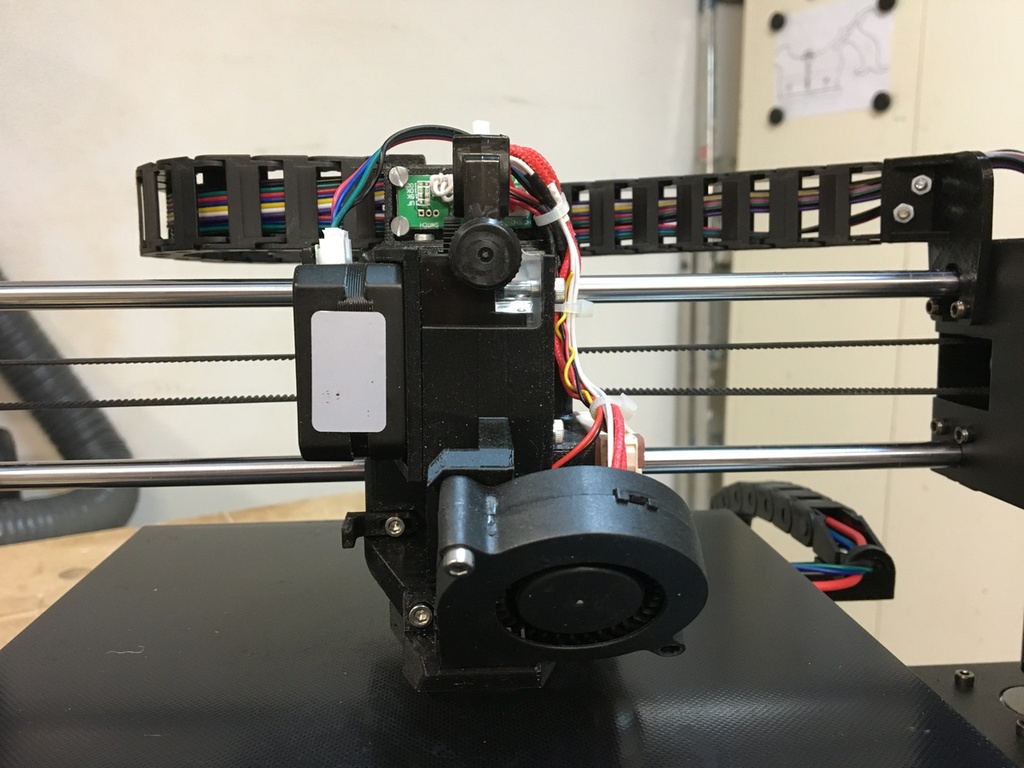

# Titan Extruder Upgrade for Anycubic I3 Mega and Prusa i3 Turn your Anycubic I3 Mega into a high-performance direct drive extruder printer with this upgrade. Watch the tutorial: https://www.youtube.com/watch?v=PVOJr0LqMk0 I drew inspiration from petrzmax's Goliathus Extruder design, but wanted to incorporate the Prusa fan duct for its exceptional airflow performance. After multiple attempts at modifying the Goliathus extruder, I decided to start from scratch and create a brand new design. ## Key Changes in this Design * Moved the hotend fan to the right side to avoid interference with the printer's X-endstop switch. * Adjustable X-endstop for precise calibration. * Integrated Prusa fan duct for improved airflow performance. ## What You Need * Titan Extruder or clone (I use TriangleLab) with pancake stepper motor. * V6 Hotend or clone. * 50x50x15 parts cooling fan. * 40x40x10 hotend cooling fan. * M3x8 screws for Nema-17 mount (2). * M3x8 screws for BLTouch (optional, 2). * M3x20 screws for X-carriage (4). * M3x10 screws (7) for hotend fan, fan duct, parts cooling fan, and adjustable X-endstop. * M3 nuts. * M3 washers (4). ## Additional Prints Required * X-Carriage: Anycubic I3 Mega Prusa i3 X-Carriage Converter. * Prusa fan duct or derivative. The Prusa Mk3 fan duct works well. ## BLTouch Installation If you want to use BLTouch, print the Nema-17 holder with integrated BLTouch mount and apply these offsets in Configuration.h: X_PROBE_OFFSET_FROM_EXTRUDER -31 Y_PROBE_OFFSET_FROM_EXTRUDER -5 Z_PROBE_OFFSET_FROM_EXTRUDER 0 **Note:** This is untested, so please report any issues. ## Assembly Instructions 1. Insert M3 nuts into the Nema-17 mount. 2. Insert M4 nuts for X-carriage into the base. 3. Assemble V6 Hotend and Titan Extruder according to their respective tutorials. 4. Mount cover and adjustable X-endstop. 5. Assemble fan duct and parts cooling fan. 6. Mount hotend fan with 4 M3x10 screws. 7. Attach whole assembly to X-carriage using 4 M3x20 screws and washers from carriage side. 8. Adjust X-endstop. When complete, calibrate the extruder expecting a higher E-steps value (around 440-450) due to gear ratio. ## Changelog ### 2019-11-23 * Redesigned base and cover for improved fan duct clearance. ### 2019-05-03 * Improved air flow of hotend cooler with redesigned base and cover. ### 2019-04-27 * Added BLTouch mount. * Included cable tie holders in the base. * Relaxed tolerances of Nema-17 mount.

With this file you will be able to print Titan Extruder for the Anycubic I3 Mega, Prusa i3 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Titan Extruder for the Anycubic I3 Mega, Prusa i3.