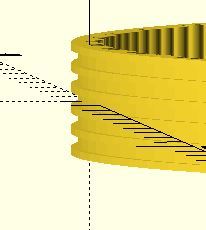

Timing Belts with back slots

thingiverse

Add HTD 3 profile and back slot for strength. The drive belt was made from Grillon Nylon 12, an excellent material that is even more taut than Nylon 6 from the same manufacturer. However, I believe it's entirely possible to make them in Flex, Nylon 6 or Nylon 12. The issue with printed belts is that they don't have a backPlain, which is the fabric or thread behind that provides rigidity and timing teeth. I changed the SCAD sheets for corread so now you can have some channels where a polyester multifilament thread (like common drive belts) or fishing line could pass through. Once the material has passed through, it's completed with a layer of SupraBond transparent adhesive or silicone to ensure any shedding is prevented.

With this file you will be able to print Timing Belts with back slots with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Timing Belts with back slots.