The Laminator

thingiverse

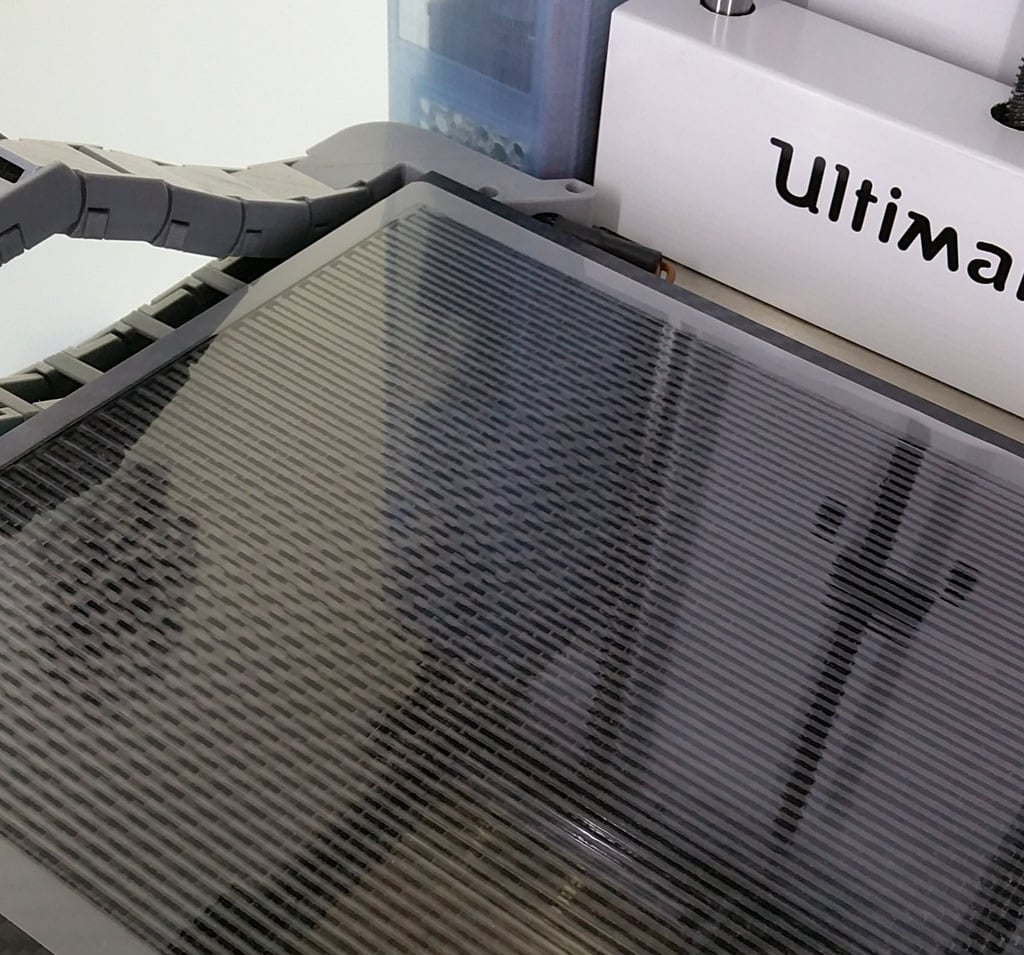

So, what is the laminator? ... And what can you do with it? ... And what can you get?\ It's exactly this: The laminator is a simple bonding agent for fixing a removable printing underlay. It fixes a hot-laminate film as a well-adherent and low-cost object support for problematic filaments, like PLA. By creating a first layer on the laminate film, the film and a carrier plate can be very well connected. Air pockets are reduced in advance or eliminated completely. This process helps avoid big waste of material due to material warping later on. Printed surfaces achieve the same gloss level as if they were printed directly on heated glass. With optimal application, it can be easily printed on the laminate film many times. I have made many other attempts to apply laminate film bubble free, but this method is currently the best for my concerns. Introduction: The laminator is a simple but reliable bonding agent for fixing a ordinary hot-laminate (PP / PE / film 0.08 - 0.12mm) on a build platform as an easy replaceable print underlay for poor adhesion PLA and other filaments. The main purpose of the laminator is good print preparation. In addition to fixation, the formation of air pockets between the carrier plate and the film should be avoided. For this, the printhead drives over the entire base area and creates a first layer already with the desired material. Almost 100% of the footprint of the Ultimaker 2 is covered, but you can make adjustments with the zoom function of your slicer. A parallel line structure is created, which must be removed before the actual printing process. You can determine if the material adhesion and temperatures are optimal for the following printing process already during and after this first step. Advantages / disadvantages: Exemplary example: PLA-HT (by Multec) adheres good to hot-laminate foil. This filament sticks very badly on most common construction surfaces, but it has many advantages during processing. There are almost no lint by retractions and driving without material. Objects with large overhangs succeed better. With this material, you can produce very detailed replicas that require very little post-processing. Special filaments or PLA grades with poor adhesion may adhere better to laminate films. No expensive BlueTape, hair spray, or other questionable bonding agent is required. Hot-laminate film can be removed at room temperature from many surfaces absolutely residue-free. I have tested it on aluminum with PEI coating. A well-aligned print bed does not need to be re-aligned because the laminate films are very thin (0.08 - 0.12mm). Reduce the initial layer thickness by about 33%. So reduce 0.3mm to 0.2mm or just 100% to 66% material flow. Important: This method is NOT suitable for filaments printed at very high temperatures above 195...210 degrees in the first layer, or when material generally needs to be kept extremely warm throughout the entire printing time. Printing with very high starting temperature leads to distortions of the hot-laminate film. Generally, a platform that is kept too hot leads to distortions of the printed objects in the transition area. Have fun experimenting with hot-laminated films...I give no guarantee at this point for success!

With this file you will be able to print The Laminator with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on The Laminator.