Test wall thickness

thingiverse

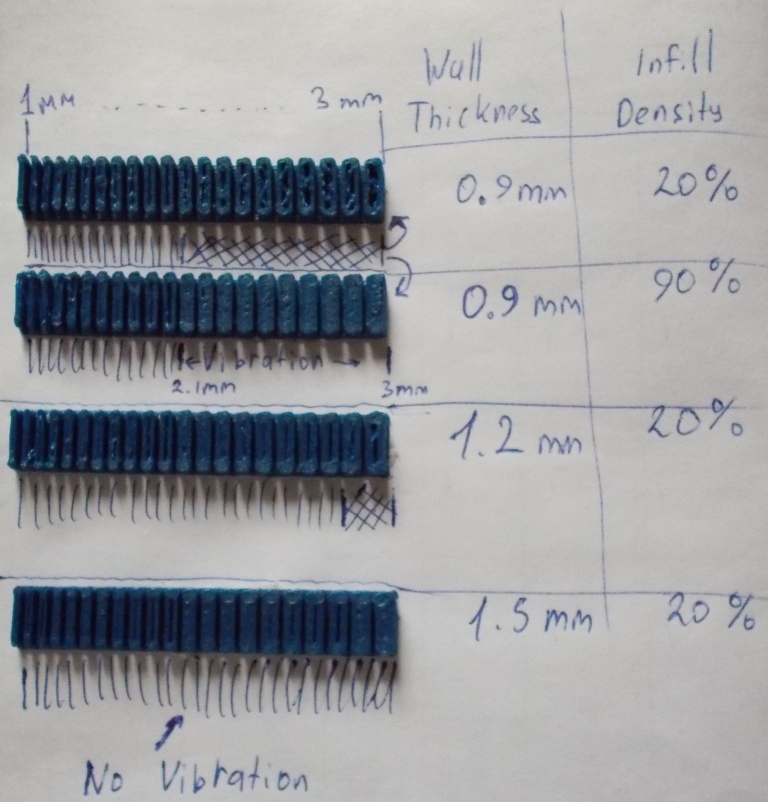

I use a program slicer Cura When printing thin-walled models (boxes, forms, cookies, etc.): 1) The slicer fails to properly fill the space inside the walls. Depending on the parameters of "Wall Thickness" and "Infill Density", voids appear inside the walls that should not be there. 2) Also, if the option "Wall Thickness" is less than 2 times the wall thickness, then the inner filling is made diagonally at an angle of 45 degrees to the line of the wall. And with a small wall thickness vibration. I think this is not good for 3D printing. For example, from vibration, the bed setting gets strayed and often needs to be reconfigured. I created this model with different wall thicknesses (1 to 3 mm). And printed it with different parameters "Wall Thickness" and "Infill Density". The result can be seen in the photo. And I came to the conclusion that for the Cura slicer, optimal wall thickness when creating models, you need to choose: 1.3 to 1.7 mm, and 2.1-2.5 mm when setting the parameter "Wall Thickness" at 1.5 mm. No vibration, the model prints faster, and the quality of the walls is the best possible - no cavities. ATTENTION!!! To see the inside of the walls, it's necessary to interrupt the test print at a height of 3.6 mm. Can you test for your printer and program slicers? Sorry for my English. Good luck ----- Test Wall Thickness I use a slicing software Cura When printing thin-walled models (boxes, forms, cookies, etc.): 1) The slicer does not correctly fill the space inside the walls. Depending on the parameters of "Wall Thickness" and "Infill Density", voids appear inside the walls that should not be there. 2) Also, if the option "Wall Thickness" is less than 2 times the wall thickness, then the inner filling is made diagonally at an angle of 45 degrees to the line of the wall. And with a small wall thickness vibration. I think this is not good for 3D printing. For example, from vibration, the bed setting gets strayed and often needs to be reconfigured. I created this model with different wall thicknesses (1 to 3 mm). And printed it with different parameters "Wall Thickness" and "Infill Density". The result can be seen in the photo. And I came to the conclusion that for the Cura slicer, optimal wall thickness when creating models, you need to choose: 1.3 to 1.7 mm, and 2.1-2.5 mm when setting the parameter "Wall Thickness" at 1.5 mm. No vibration, the model prints faster, and the quality of the walls is the best possible - no cavities. ATTENTION!!! To see the inside of the walls, it's necessary to interrupt the test print at a height of 3.6 mm. Can you test for your printer and program slicers? Good luck

With this file you will be able to print Test wall thickness with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Test wall thickness.