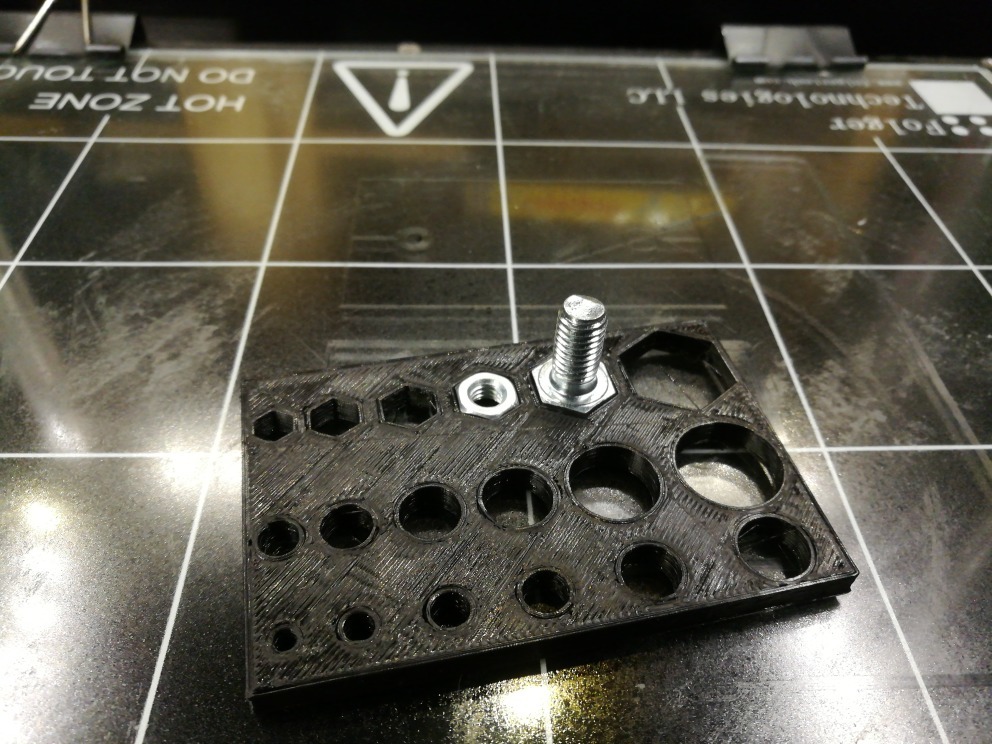

Test pattern for dimensionally accurate openings in 3D printing especially for fusion 360

thingiverse

Test Pattern for Dimensionally Accurate Openings in 3D Printing: As a rule, all openings are printed smaller than those found in construction. This file is used to correct integer diameters, metric screws, and nuts. Please note that the holes already contain a correction factor, making them slightly larger than the corresponding component. CSV File with Metric Nuts and Bolts: This CSV file can be easily imported into Fusion 360 as a parameter table via the "Parameter I / O" plugin. The values can then be used directly in the sketch. With the STL file, you can check the dimensional accuracy of your own printer. Then adjust the values directly in the CSV file or in Fusion. Please also test whether the printer supplies holes with different dimensions in the Z and XY directions. If you use this table in Fusion, you can quickly switch to another printer by defining all holes as parameters. Enclosed is the Fusion 360 file. I hope it saves you a lot of time and material. Content of the Test Print: M10, M8, M6, M5, M4, M3 each for: - Wrench size hex nut - Head diameter Inbus screw - Screws/shaft diameter in integer mm All with a correction factor for larger holes!! Operating Procedure: 1. Test print and check if the openings fit. 2. If necessary, adjust values. Possibilities of Adaptation: 1. In CAD directly. 2. In the CSV file with import to Fusion 360. 3. Directly in my Fusion file. The table also contains data on the height of nuts and screw heads.

With this file you will be able to print Test pattern for dimensionally accurate openings in 3D printing especially for fusion 360 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Test pattern for dimensionally accurate openings in 3D printing especially for fusion 360.