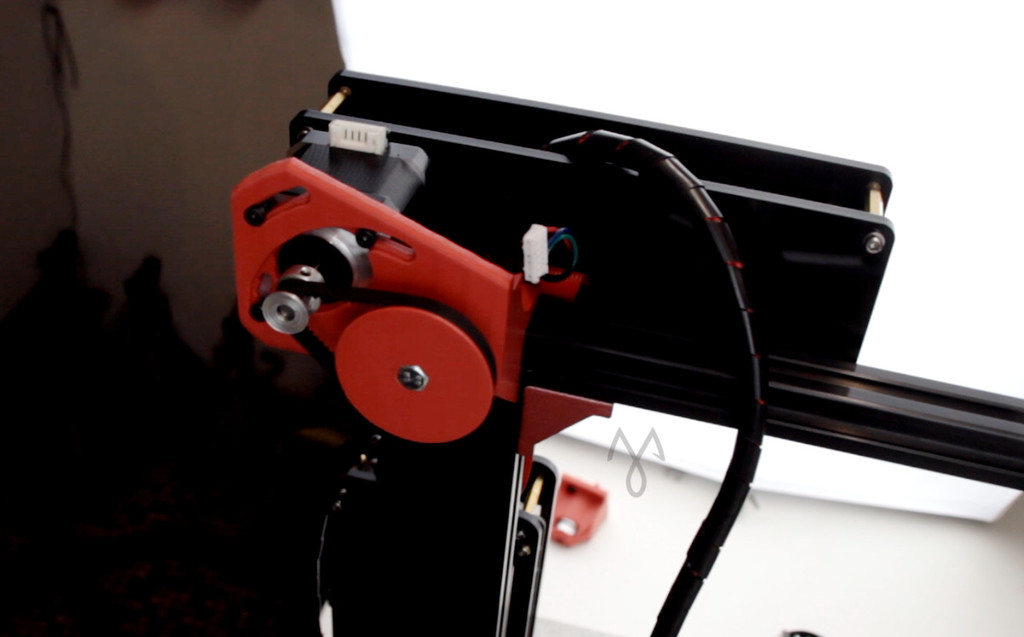

Tarantula Belt Driven Z axis

thingiverse

A Simple Solution For Perfect Prints Every Time Forget about unnecessary printed brackets and dual lead screws - a belt driven system is the way to go for precise prints. BOM: 1x GT2 20T pulley 1x GT2 20T idler pulley 1x GT2 80T belt loop 1m GT2 6mm belt 1x M5*30mm Hex screw 3x M5 grover washers 1x M5 Nylstop nut 2x MF105 bearings 1x 6mm bronze spacer (or a stack of washers) 4x M3*10mm DIN912 screws 8x M4*10mm button head hex screws 8x M4 T-nuts for 2020 6mm aluminum profile 1x Nema17 motor (17hs4401 recommended) Assembly Video: https://youtu.be/IgWcZoRDe20 Mounting for the E3D Titan + V6 + 5015 fan can be found here: https://www.thingiverse.com/thing:2624164 June 3rd, 2018 I recently spoke with a maker who experienced a small fall of the gantry at the end of a printing sequence. My response was: "When the holding current of the Z motor is turned off, the gantry overall weight exceeds the motor's rotor inertia, and there's a little fall of the gantry. I experienced this same issue when I upgraded my printer to a heavier direct drive feeder. To resolve this, consider upgrading your Z motor to a longer model (17hs8401), or estimate the 'release distance' (4 millimeters here) and insert a Z raise into your gcode end sequence before releasing the holding current (M18 command). Alternatively, use a larger ratio on the belt reduction, but be aware that this may require a larger motor." Long story short: the design of this belt driven system aims to provide enough precision for thinner layers without slowing down the operation compared to a screw drive. The holding torque is designed to securely exceed the gantry weight in operation with the motor provided in the Tevo's kit. Note: The fall only occurs on some printers (upgraded gantries, not so tight wheels...) when motors are turned off at the end of a print, and does not affect prints, even in longer print times. I completed huge and complex 43h prints with no issue. June 24th, 2018 I'm glad manufacturers like LULZBOT implement Belt Driven Z Axis on their machines (Cf. LULZBOT Mini 2). IMHO you may find a growing number of printers replacing T8 screws by belt system Z axis because it solves the Z wobble effect and makes the homing sequence much faster. There are two FAQs about this system: first, how can this be any better than screw? Well, in this price range, the screw and its nut's manufacturing is not as accurate as required. The flexible coupling brings some issue, especially because the screw is not supported both sides. Second, why keep driving the gantry in one side when one of the most popular upgrades is a screw on both sides? A gantry positioning issue comes from the guiding system and not from the driving system. October 3rd, 2019 I had a nice comment from a long time user, thanks for the feedback Klaus: "Wanted to say TY again for this mod - i have been using it now for many months, and it is the best mod for the Tarantula i have tried. No Zbanding, absolute perfect print quality on surfaces, and microstepping works as well btw :) Did some small changes to use metal gear versions of the gears instead of printed ones, but the basic design is sound and amazingly well executed." November 19th, 2019 A friend reported the "falling Z issue". Normally with a medium size Nema 17 motor the problem never happens. I asked him to bring his printer to my home for a complete check. The issue was pretty simple and I did not expect that: the Z belt was not tensioned enough. So if you experience the Z falling issue, please be sure your Z belt is tensioned properly.

With this file you will be able to print Tarantula Belt Driven Z axis with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Tarantula Belt Driven Z axis.