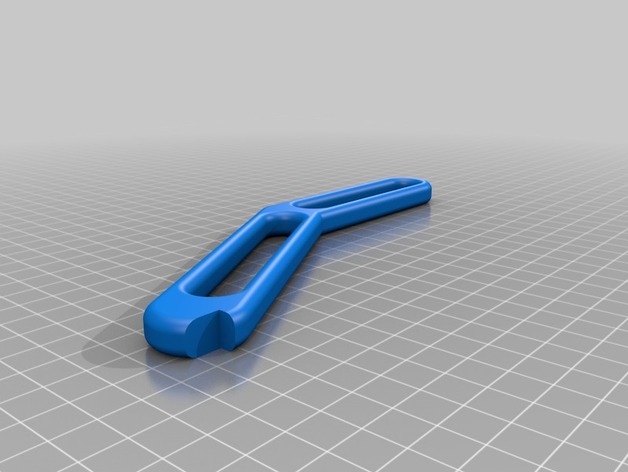

Table Saw Push Stick

thingiverse

A Simple Push Stick: Protect Your Fingers While Cutting Keep a push stick near every tool where you might cut small pieces, 3-4 of them will do fine. They're designed to be slightly springy to keep pressure steady on your workpiece. Keeping wood tight to the table and fence is crucial for accurate and safe cuts. Using one of these with a featherboard will get you great results. You can find the Milescraft yellow plastic featherboard on Amazon for under $15. Although they could be bigger, they work quite well, even with my 9" saw blade. If you have a 12" saw, though, you'll likely need something bigger. I already chipped one with the table saw's blade, but it still works fine. The stick only lost a small plastic chip. Printed on my Replicator 2X in ABS, I wanted to avoid the stiffness and hardness of PLA in case the push stick hit the saw blade. I may try printing them again using polystyrene (the material that comes with the limonene) since it's softer than ABS. If they do get cut by the blade, I want it simply to snap. Printing Settings The standard print quality used was something like 5 shells and 25% infill. This created springy rails without making them too stiff or weak. Because of low surface area touching the build plate, the rails may try to curl up when they come off. Level your build plate perfectly before printing, using my leveling pattern. Apply ABS glue/slurry or Aquanet to Kapton tape before starting print and keep ends from warping with either.

With this file you will be able to print Table Saw Push Stick with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Table Saw Push Stick.