Syringe pump

thingiverse

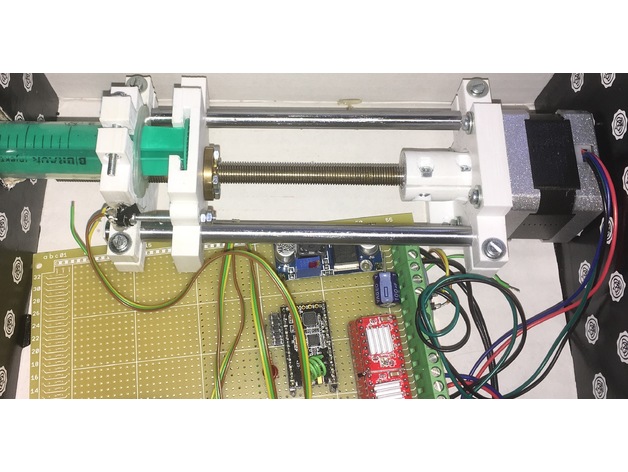

I was searching for a syringe pump to automate fertilization of my nano cube. My first attempt with http://www.thingiverse.com/thing:539490 failed due to mechanical instability. Many syringe pumps projects exist on thingiverse, so I chose the design from http://www.thingiverse.com/thing:536373. This choice was perfect for my printer's 80x80mm print bed since all parts fit within its dimensions. However, I made several modifications to ensure the syringe pump worked effectively for me. The original design had some issues that needed to be addressed. Firstly, the distance between holes for the NEMA17 stepper motor was not adequate, making it impossible to mount the motor properly. Secondly, the motor holder lacked holes to secure the syringe pump to a plate or similar surface. I made a crucial change by fixing the shaft of the syringe to the slider, allowing liquids to be pushed and pulled easily. This modification enabled me to load fertilizer into the syringe without disassembling the entire pump. I also added a mounting hole for an end stop signal when the syringe is empty. The dimension of my used messing antriebsschraube was different from what was specified, so I adjusted the slider accordingly. Additionally, I found it essential to use linear bearings for the slider, which required changing the hole diameter to accommodate a normal LM8UU bearing or even printing one myself. Despite some limitations, the syringe pump works well, but with a mechanical slackness that occurs when changing direction (from push to pull or from pull to push). However, this issue is not significant in my case since I load the entire syringe and then push a small amount of fertilizer to reset the slackness. After this, the direction remains unchanged due to the minimal daily fertilization requirement. Feel free to use these mechanical parts; I designed the electronic components using an panStamp AVR module and integrated them into my smart home system FHEM. The source code is available for download in the specified section. Print Settings: Printer: Fabrikator mini, Tiny Boy Rafts: No Supports: Yes Resolution: 0.2mm Infill: 20% Notes: Support is only necessary for the slider; the other parts do not require support. Twenty percent infill works well for me, as there is no significant force exerted on the parts. Post-Printing: Parts Needed: 2pcs. linear rods, 8mm diameter, 150mm length 2pcs. Linear bearings LM8UU or print your own 1pcs. NEMA17 stepper motor 1pcs. trapezoidal screw (T8 8mm, 150mm length) with brass copper nut (T8-1-D1) Electronic components to control the pump; I chose a panstamp AVR 1 connected to fhem Some M3 screws and nuts. Print and Assemble: Print all three parts. There is nothing special about this process. When mounting the linear rods, try to align them in parallel to avoid the stepper motor losing steps when the syringe is nearly empty. Syringe Pump in Action: Pump 500µl

With this file you will be able to print Syringe pump with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Syringe pump.