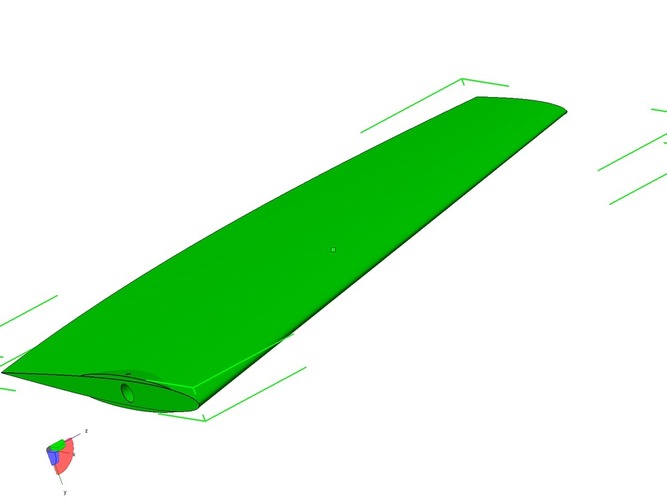

Surfski rudder plug for moulding/casting from.

pinshape

Human: 240mm deep, volume of 165 cubic centimeters. Much narrower than carbon fibre think rudders. Aluminium has a density two point seven times that of water, so an aluminium rudder with these dimensions will weigh approximately 280 grams when submerged. To shield the surface you can use a wire brush, anodize, and dye....search for it online. The rudder features a tapered shaft entry, eight millimeters tapering to four millimeters in diameter over a length of sixty millimeters. There's also a recess for drilling and tapping a grub screw, but it's better to carve some gripping notches into the stainless steel rudder shaft and encase the aluminium around it. Look up sand casting and obtain silica sand and bentonite clay, build a moulding box with greater inside dimensions than the fin outside dimensions. Alternatively, you can create a mould around it and then cast carbon fibre etc. using some low viscosity epoxy resin. Try to find a supplier of infusion moulding resins for best wetting out characteristics. You can also scale the rudder in your slicing program to use in a plane for tail, wing or rudder sections. As a wing, it will provide neutral lift so it's ideal in an acrobatic plane requiring flight on either side up.

With this file you will be able to print Surfski rudder plug for moulding/casting from. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Surfski rudder plug for moulding/casting from..