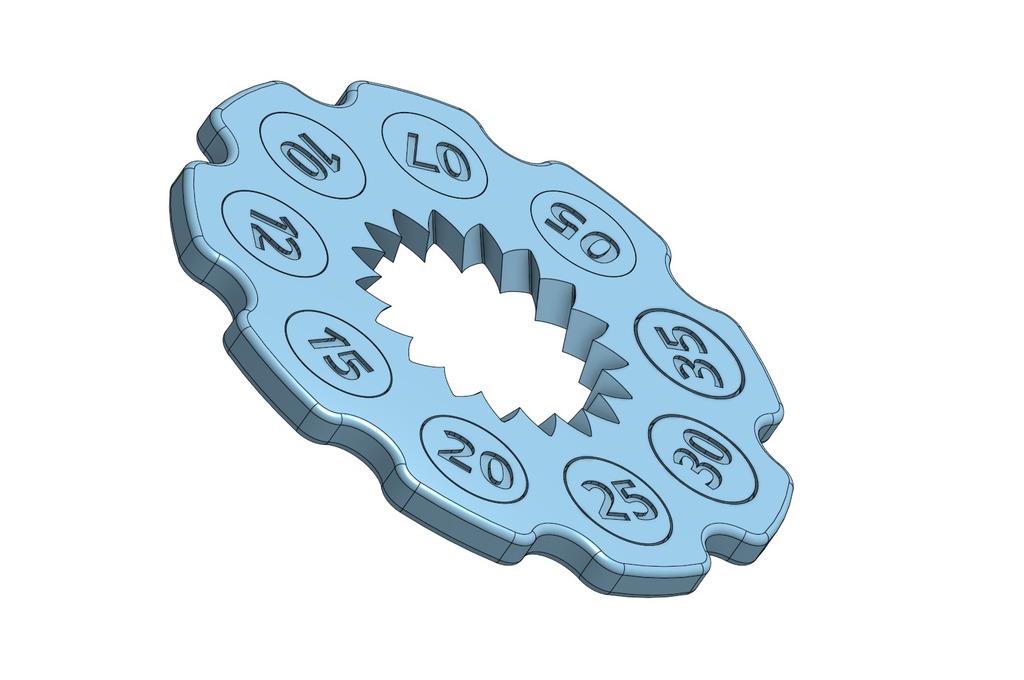

Super Tolerance Test (0.05 mm to 0.35 mm, 9 samples in one)

thingiverse

I made this tolerance test, because the others weren't enough. It has a wider range of tolerances and is slimmer, so you won't spend many hours testing your printer. Here's a fact sheet: * You only need 4mm for parts to feel solid and rotating pieces to be held in place. * You don't need these high tolerance tests (0.6+ mm). If your printer can't print with 0.3mm even with a 1.2mm nozzle, something is wrong and you should fix it instead of testing. Tolerance tuning requires material expansion compensation. Modern 3D printers are precise machines that should step N steps in M direction every time. The problem is the extruded material smears slightly after adhering to previous layers (including the bed). You think you have a 0.4mm nozzle, but it prints 0.6mm thick lines because molten plastic drifts away before cooling enough to solidify. This is how it should be. If it cools down too fast, it won't melt the layer underneath and won't adhere. Get the latest Cura and configure your material expansion compensation. Forget about tolerances once and for all. Sources: https://cad.onshape.com/documents/e4dec0750e4db247b90369b1/w/37ebdcecc64073de18cbd1b6/e/57ec038a79053a91fc1abaf6

With this file you will be able to print Super Tolerance Test (0.05 mm to 0.35 mm, 9 samples in one) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Super Tolerance Test (0.05 mm to 0.35 mm, 9 samples in one).