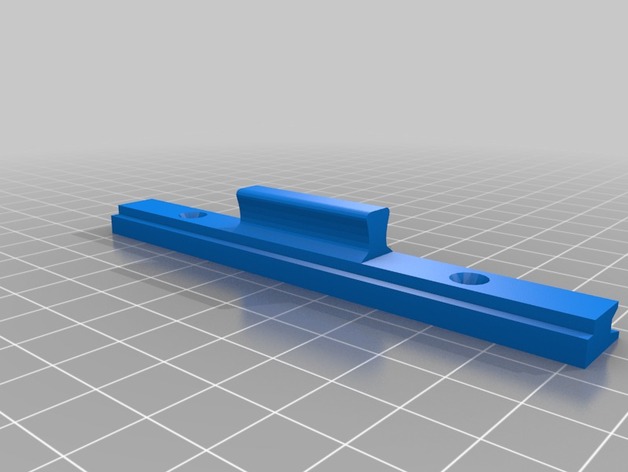

stickvise jaws

thingiverse

Build Your Own Jaw For A Customized Vise System DIY enthusiasts are constantly looking for ways to create their own tools and equipment, and one popular project is building your own jaw for a vise system. Understanding The Basics ------------------------ A vise system is an essential tool in any workshop or garage. It provides a secure hold on various materials, allowing you to work with precision and accuracy. However, many DIYers find themselves lacking the necessary funds to purchase a high-quality vise system. Building Your Own Jaw For A Vise System ----------------------------------------- This project will guide you through the process of building your own jaw for a vise system using readily available materials. You'll learn how to design, fabricate, and assemble the components needed to create a sturdy and reliable vise jaw. Materials Needed ---------------- * 1/4 inch thick steel plate (for the jaw base) * 1/2 inch thick steel rod (for the jaw support) * Aluminum or steel tubing (for the vise frame) * M10 or M12 threaded rod (for the jaw pivot) * Washers and locknuts * Drill press and drill bits * Measuring tape and calipers * Safety glasses and a dust mask Step 1: Design The Jaw Base ----------------------------- To begin, you'll need to design the jaw base using a computer-aided design (CAD) software or by sketching it out on paper. Consider the size and shape of your vise system, as well as the type of materials you'll be working with. Step 2: Fabricate The Jaw Base ------------------------------- Using a metal cutting saw or a bandsaw, cut the steel plate into the required shape and size. Sand the edges to smooth them out and remove any rough spots. Step 3: Assemble The Vise Frame -------------------------------- Cut the aluminum or steel tubing to the required length and assemble the vise frame using a drill press and threaded rod. Make sure everything is securely tightened before moving on to the next step. Step 4: Attach The Jaw Pivot ----------------------------- Using the M10 or M12 threaded rod, attach the jaw pivot to the vise frame. This will allow you to easily adjust the jaw position and ensure precise alignment. Step 5: Assemble The Vise System -------------------------------- Finally, assemble the vise system by attaching the jaw base to the vise frame using the washers and locknuts. Make sure everything is securely tightened before testing the vise system. Conclusion ---------- Building your own jaw for a vise system can be a fun and rewarding DIY project. With these steps and materials, you'll have a sturdy and reliable vise system that will last for years to come. Just remember to always follow safety guidelines and use proper techniques when working with power tools and sharp objects.

With this file you will be able to print stickvise jaws with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on stickvise jaws.