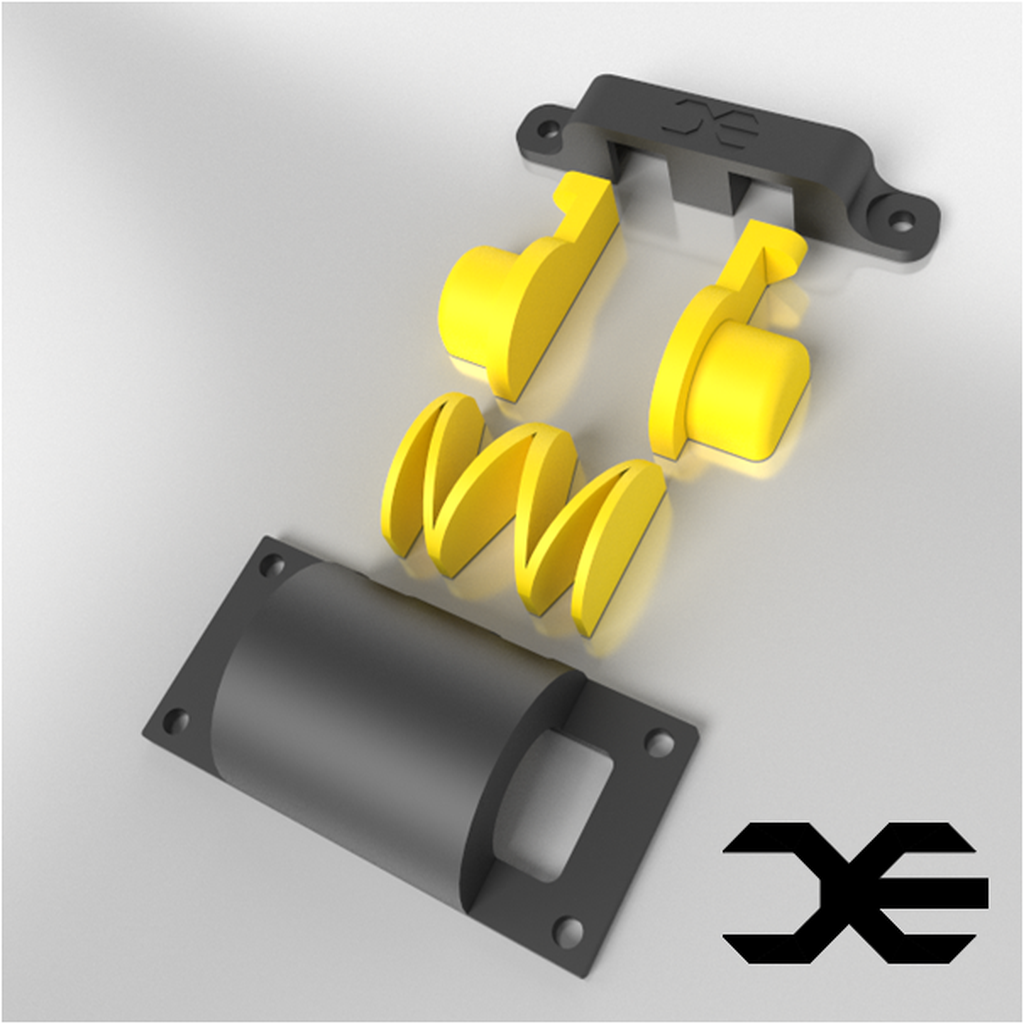

Spring-loaded latching mechanism

thingiverse

This is a versatile spring-loaded latching mechanism for numerous applications. It draws inspiration from the slam latch commonly found on normal doors and some car doors. However, unlike its counterparts, this one cannot be slammed into place; instead, you must press the pins to release the connection and form it. Use: You attach the cage (with pins and spring inside) on one side and the anchor on the other side (i.e., box and lid). At a scale of 100%, the screw holes fit M3 screws. By pressing the two pins deeper into the cage, you load the spring and open the connection. By releasing the pins, the mechanism closes, and the spring unloads. The force of the spring is sufficient to hold the components in place and secure the connection. I have no data on the lifespan of the spring, but it appears to be holding up well. And again: slamming the parts together will not create a connection; you need to push the pins. Printing: I printed at 100% and 66.66%. At a scale of 100%, the wall thickness is a sturdy two to three millimeters. The anchor, pins, and cage are straightforward prints, requiring no special attention. Maximum bridging is between seven and eight millimeters. Most printers should be able to handle that. (If not, possible fixes: slower print, thinner layers, more cooling) However, the spring requires special care: it needs to be printed solidly by increasing the wall thickness in your slicer (>3mm). Print slowly for best results. Print all parts with 0.1 (spring or others scaled down) or 0.15 (others) mm layer height. Post-processing: Make sure you remove any remnants of a brim (if used, it's not necessary) and the first-layer squish for the mechanism to work perfectly. For the spring: take the spring and slowly compress it to its minimal form. Repeat this process a few times. If it breaks, tweak your print settings. If it holds, assemble it. Benefits of this model: * Fully 3D-printed * allows multi-color assemblies * relatively easy print * no support or printbed-adhesion necessary (normally) Drawbacks of the model: * applicable force depends on the scale * risk of components not aging/wearing well Another, perhaps more sturdy latch can be found here: https://www.thingiverse.com/thing:3969571 Designed with FreeCAD, quickly rendered with CADRays. Conceivably Engineering - Little competence, big smiles.

With this file you will be able to print Spring-loaded latching mechanism with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Spring-loaded latching mechanism.