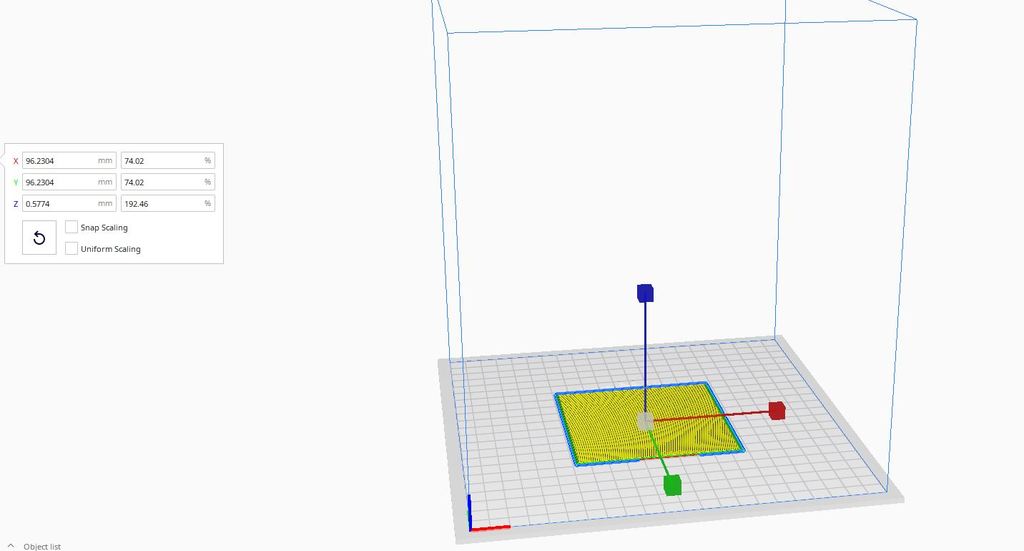

Special thin raft to safe material and have adhesion.

thingiverse

Hey printer buddys. I had the intention to share my idea to safe some material while enjoying the results. After i pissed away about 6-10% material on printing raft under a part, i came up with the idea to design a 0.6mm thin supoort layer. For my prints that worked well. I use a Ender 3 pro and the adavantage of that easy printer is you can lift the "X" axis slightly from hand. Just about 0,2-0,4mm so the plastic sausage get sprayed/layed perfect on the bed. I got away from place a paper under the nozzle to complicated. Grab the x axis bar and lift until perfect easyier it wont get. The left two screws to lift or lever the bed on the left side i have to use so the bed gets a flat surface, off course that will not change. Yes the part has to be placed on or in the featherthin raft but i rather los 1-2 layers 0,6mm of a part, then 8-10% raft extrusioned plastic waste. But i just lift the "X" axis as i go. Why i do that? I often change the printer adjustments especialy extrusion and line print width that infulences the sausage that gets extruded. I use a hot bed with a simple glasssheet 2mm thick, without any adhesives succsesfully. Under the part adjustments you can change the size of the featherthin raft.

With this file you will be able to print Special thin raft to safe material and have adhesion. with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Special thin raft to safe material and have adhesion..