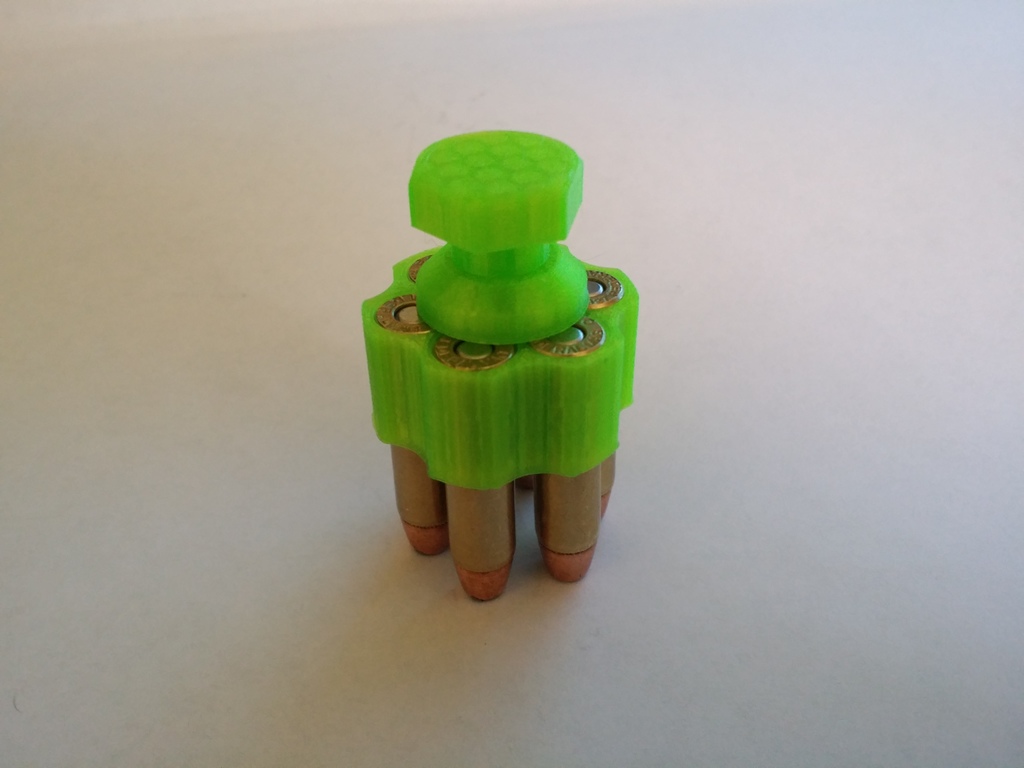

SP101 (.327) Speed Loader

thingiverse

**UPDATE** 7/6/17 Couple of improvements boost speed loader efficiency. First, I added grooves to the bottom of the body to simplify center shaft insertion without compromising detent flexibility. Now you can easily guide detents into the holes in the body without weakening "clicking action". The shaft itself has been reinforced around the flexing area, and the bottom feet have a tighter gap. This fix has also resolved the issue of the shaft being able to turn a full 360 degrees within the body when too much force was applied. The detents should now only travel the originally intended 30 degrees. I had to do some cleanup on my first layers of the body and the gap in between the center shaft's feet, but I'm extremely impressed at the outcome. Much better than the original shafts locking and clicking ability. This new shaft requires the new body. If you try to put it into the old body, it simply won't fit, but nothing stops you from cutting your own guide grooves into the bottom of the old body to accept the new shaft. If you experience detents not clicking from open to close, just cut some gap away in between the feet of the center shaft. I'm trying to keep tolerances tight so the speed loader will last a long time, but I know not all of us have the same printers or use the same settings. So always make sure you trim and test before gluing! Hopefully soon, we won't need glue at all. That way parts will be easily replaceable if needed. Speed loader for Ruger SP101 .327 caliber revolvers designed to be 100% printed with no springs or ball bearings required for assembly. Also, no supports are needed as the parts simply glue together once you're happy with the release of the rounds. (Some trimming/sanding may be necessary for proper fit.) I used PLA with good success for this print. When inserting the shaft with detents on the sides, it's best to line up detents with corresponding holes inside the body. Constant removal of the shaft or improper assembly can cause PLA to lose strength, weakening "clicking action". Another material designed to flex without breaking may be a better choice for the center shaft. I made this loader with counter-clockwise release and plan on making a few tweaks down the road. Like having all pieces snap together instead of using glue, and also improving the detent system. But for now, I'm enjoying mine; they seem to work fairly well. Even better once you start using them more and the plastic breaks in.

With this file you will be able to print SP101 (.327) Speed Loader with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on SP101 (.327) Speed Loader.