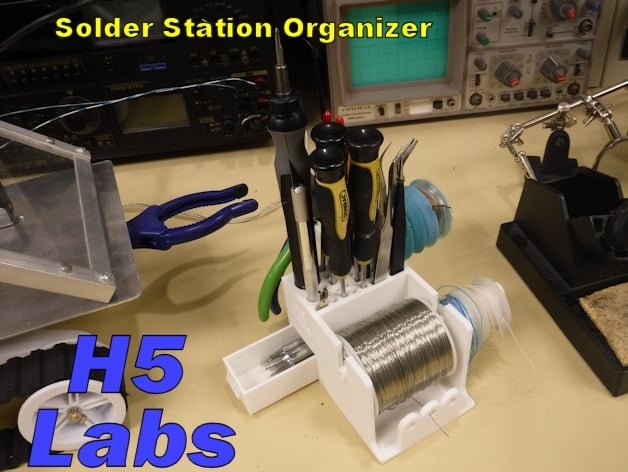

Solder Station Organizer

thingiverse

We desperately required a thorough clean-up of our solder station area in the lab, so I designed this solder station organizer to house all our soldering-related items in one compact storage unit. The design is relatively modular; you can decide whether or not to use the drawer, rear arm, right arm, or solder spool axle extensions. We utilize the base of this organizer to store: small Phillips head and slotted screwdrivers, soldering iron tips (in the drawer), various tweezers (8 pairs), small round and flat files, 30AWG wire stripper, pick/hook tool, X-Acto knife, small powered screwdriver (flux pen may fit in this hole), -small side cutters, We use the rear arm to store a pair of pliers. We use the right arm to store four spools of desolder braid. And, we use the solder spool axle extension (one or two can be used) to store small spools of 30AWG wire. The solder spool area can accommodate one 63mm wide spool of solder (using the middle guide hole), or two smaller spools of solder totaling 63mm wide or less (using the two outer guide holes). We also have two versions of the base; one has a rear brim/shelf to help prevent warping of the rear wall when printing (the rear brim/shelf can be removed after printing, if desired), and the other version does not have this rear brim/shelf if you have your process dialed in and are capable of minimizing warping in your prints. Update 10/9/2018 - Added 15mm extended height rear arm to accommodate larger hand tools as needed. This file is not part of the "complete" ZIP file sets, so you will need to download this in addition to the complete ZIP file of your choice (if you need it). Print Settings Printer Brand: MakerGear Printer: M2 Rafts: No Supports: Yes Resolution: 0.3 Infill: varies - see notes Notes: We used MakerGear PLA with bed temp of 70C and extruder temp of 220C. Base: 25% or more infill (we used 25%). Supports only needed in the drawer cavity. The rear of the base has a tendency to warp a bit due to the size of the print. This is largely cosmetic, but can interfere with the drawer operation if too severe. This can be mitigated by following some or all of the following steps: -Have the drawer cavity support structures make contact with the back wall of the drawer cavity. -Increase bed temperature (we used 70C, but had some minor warpage - I recommend going 80C or 90C). -Reduce extruder temperature (we used 220C. Going lower may help, but be cautious as going too low can result in extruder issues). -Print the base version with the rear shelf/brim. This feature was added to help reduce warping of the rear wall and can be removed after printing or left in place to provide a lower support shelf for items hung from the rear hook. -Print with lower infill percentage. -Print using an enclosure. Rear Arm & Right Arm: 100% infill, supports needed underneath arm area when printed as shown in model file. Drawer: 25% infill, no supports needed Solder Spool Axle: 100% infill, supports needed on bottom ledge when printed as shown in model file. Axle Extender: 100% infill, no supports needed when printed as shown in model file.

With this file you will be able to print Solder Station Organizer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Solder Station Organizer.