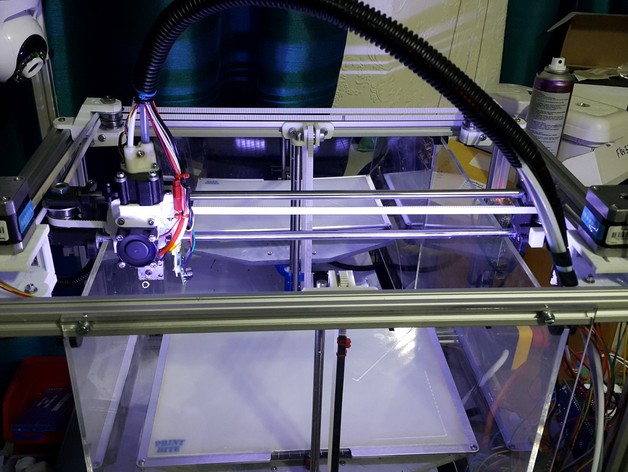

SmartRapCore Alu - DjDemonD Adjustable Motor mounts, Belt Geometry fix for 608zz bearing pulleys

thingiverse

Update 31-08-16: The machine is much quieter with these mounts; the motors are now much better isolated from the frame acoustically, an unexpected improvement. Okay so there are several issues with the SmartRapCore Alu: 1) As with all corexy machines, getting the machine to print correct sized parts in x relative to y requires adjusting the belt tension from the A belt relative to the B belt. This is difficult on the SCALU machine as the only way to do it is to pull belts out of belt clips and move them one belt tooth (2mm) one way or the other. I tried to get around this by making a balanced belt tension carriage, but it still doesn't work perfectly. 2) The motor mounts also serve as y-rod holders at the front, which are not great. I have never been happy with my y-rods being perfectly aligned or held firmly enough to ensure good print quality. Plus, the left and right sides had different mountings; this never seems like a good idea. 3) The big one - belt angles: this thread on the reprap forum makes clear the reasons why the belts must be parallel to each other along the x direction and turn at exactly 90 degrees from the y slides to the back idler pulley and front drive pulley. Any deviation from this will cause objects not to be square, especially at the edges of the bed. In the original SCALU design this might have been correct but with 608 bearings the geometry changes, and the pulleys are not perfectly aligned with the y-carriages. So these motor mounts are designed to solve all three problems: 1) The x and y (a and b) motors can now slide around 10mm, making it easy to adjust the relative belt tension. 2) They are derived from the rear pulley holders; my version has fully supported pulleys, so they hold the y-rods firmly and precisely in alignment with the rear pulley holders. No more odd asymmetrical fixings like those found in the original SCALU design. 3) The pulleys are now positioned so that the belt turns exactly 90 degrees from the y-carriages to the drive pulley. Please be aware my machine has f608zz bearings and not printed pulley sleeves, so the geometry for the pulleys is based around that. I have no intention of doing a version for printed pulley sleeves as they are not accurate and 608zz bearings work well. Please excuse the PETG prints; the quality is not what I usually produce, they're dimensionally accurate but the surface finish needs some tweaking. Please do mess with these designs - I've made the files public in Tinkercad: https://www.tinkercad.com/things/hLgH3rUWW9M-scalu-adjustable-motor-mounts-608zz-bearing-version/ Print Settings: Supports: No Resolution: 0.3 Infill: 50% Notes: I printed them in PETG but ABS would work. No support is needed if printed as orientated in the original files. There's one tiny area near to the hole for the y-rod, around halfway up, which has to print in mid-air but it prints like a bridge and wasn't a problem.

With this file you will be able to print SmartRapCore Alu - DjDemonD Adjustable Motor mounts, Belt Geometry fix for 608zz bearing pulleys with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on SmartRapCore Alu - DjDemonD Adjustable Motor mounts, Belt Geometry fix for 608zz bearing pulleys.