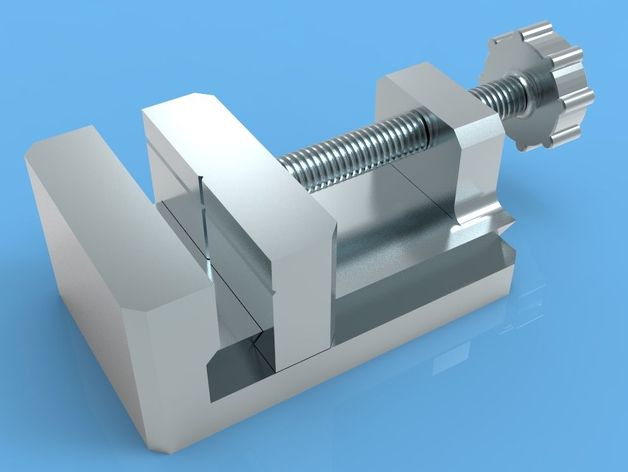

Small Desktop Vise

thingiverse

This was modeled after a miniature toolmaker's vice, ideal for holding small parts for gluing or soldering tasks. The rear jaw glides smoothly on a dovetail fixed within the base. The screw threads are an ACME thread approximation, which should operate without any issues once it is fully broken-in. When initially inserting the screw, you'll likely encounter significant resistance due to its tight fit. However, if you approach this process methodically and gradually increase the screw's insertion each time after backing it out slightly, it will eventually settle in place and turn easily with no backlash. Take your time and avoid forcing it too aggressively. My primary objective for this design was to minimize complexity while ensuring ease of printing. The only additional parts needed for assembly are four M3x20 cap-screws used to secure the screw block to the base. I tapped these holes using an M3 tap, but you can also attempt to create your own threads by forcing the screws if you lack access to a tap. Prioritize seating the screws into the screw block before attaching it to the base. The ball on the end of the screw shaft is inserted into the pocket on the rear jaw via a press fit. With moderate force, this should seat securely in place. However, if your rear jaw fits too tightly (i.e., "drags"), the ball may pop out when retracting. The overall length of the base measures 116mm, with a maximum jaw opening of approximately 61mm. PLA appears to be the optimal material choice due to its superior strength and rigidity in comparison to ABS. I employed Hatchbox PLA for this project, which tends to exhibit reduced brittleness relative to other brands I've used and shows minimal warping tendencies when printed – a crucial consideration when fabricating the base. Print Settings: Printer: Custom-built Kossel 2020 Rafts: None Supports: None Resolution: Between 100-150 microns for threaded components Infill: 50% or higher for the screw block Notes: Print threaded parts at a heightened resolution with ample cooling. The included parts are optimally oriented for printing purposes. No reorientation is necessary, and supports should not be required. The four holes for M3 cap-screws in the counterbore feature tapered bottoms to eliminate support necessity and produce clean holes. Post-Printing: No gluing is necessary; instead, attach the screw block to the base using 4x M3x20 cap-screws. The front wedge on the screw block transfers axial loads away from the screws when tightening the vice. Design Process: This design was created in DesignSpark Mechanical – an exceptionally fast and intuitive free CAD software ideal for 3D print design.

With this file you will be able to print Small Desktop Vise with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Small Desktop Vise.