Singer Nähmaschine / sewing machine 6xx (670g, 631g, ...) electronic conversion parts

myminifactory

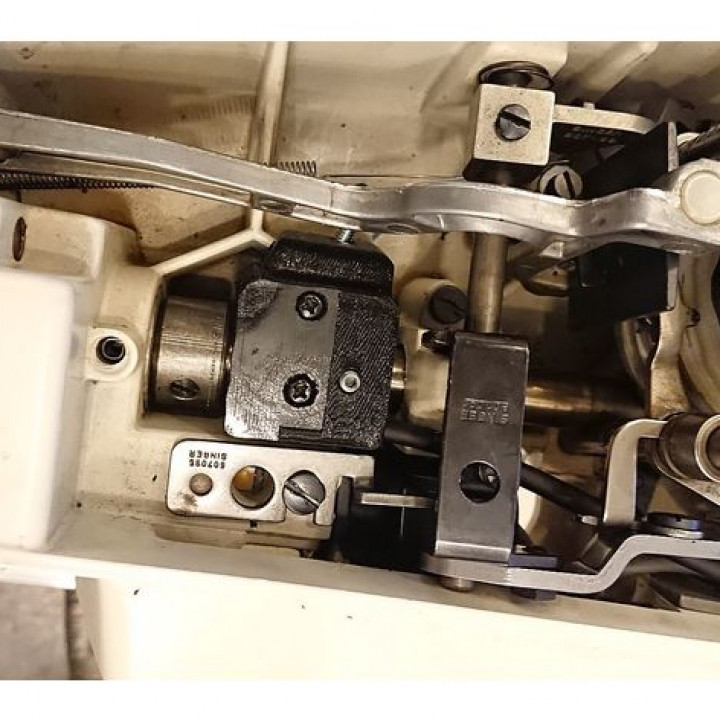

3D-gedruckte Teile zum Umbau einer Singer 6xx aus den 1960ern auf einen BLDC-Motor und einer elektronischen Nadelpositionierung (oben/unten, einstellbar durch den Bernina-Fußanlasser LV1 mit integrierter Nadelpositionsumschaltung: Adapter zum Einbau einer Niedervolt-Steckverbinderbuchse für das Pedal und einer Lemo-S-Einbaubuchse für das Netzteil anstelle der originalen Singer-Buchse. einstellbarer Halter+Schutzgehäuse für Reedkontakte zur Montage an der Hauptantriebswelle Gehäuseteile für die Elektronikplatinen Hinweis: Die Datei "Reedkontakttraeger_einfach.stl" wird nur benötigt, falls der 3D-Drucker den Reedkontaktträger nicht brauchbar druckt. Dort sind die Schlitze etwas breiter und leicht vereinfacht, man muß aber die Reedkontakte mit Klebstoff fixieren. Die vollständige Umbauanleitung ist hier zu finden: https://www.mechanotronikum.de/index.php/36771-singer-631g-version-2-0-teil-1.html Gedruckt aus PETG (PLA sollte aber ebenfalls funktionieren). Druckeinstellungen: Layerhöhe: 0,15mmInfill: 30%Verwendete Hotenddüsengröße: 0,4mm -------------------------------------------------------------------- Some 3D printed parts needed to convert a Singer sewing machine from the 1960's to a BLDC motor, with automatic needle up/down ability (controlled by using a Bernina pedal): adapter for a low voltage connector plug for the pedal and a Lemo S series connector to fit into place of original connector. Very tight fit for the connector nuts - you may need to sand the edges or simply glue the connectors in place without using nuts. adjustable holder to fit reed contacts around the main axis of the sewing machine in order to read needle position, constisting of main part "Halter", reed contact holder "Reedkontakttraeger", cover "Abdeckung_Halter" and a position aid "Positionierhilfe". cases for the two PCBs Since the reed contact holder might be rather demanding for some printers, a simplified version ("reedkontakttreger_einfach") is also available, where the wire slots are slightly broader and a bit simpler. You my need to glue the reed contacts there to secure them though. The holder is made for two Ø1.5mm/height 0.5mm neodym magnets and two Ø1.8mm/length 10mm reed contacts (e.g. PIC PMC-1001). Cable for connection can be any 3- or 4-wire cable with 4.5mm nominal outer diameter (I used Lapp Unitronic LIYD11Y 4x0,14). Detailed instructions with photos (in german) can be found here: https://www.mechanotronikum.de/index.php/36771-singer-631g-version-2-0-teil-1.html The cases and the connector adapter ought to be self-explanatory. For the reed contact holder, please observe the following steps after printing: Cut M4 threads into the two 3.2mm holes in part "Halter" and insert M4 grub screws. Take off upper lid of sewing machine. Insert part position aid into main part, align cutout of position aid with cutout of holder and push the assembly onto the sewing machine main shaft (refer to picture on placement - assembly should have slight press fit if print is correct). Rotate machine handwheel until thread lever arm head has just risen above machine housing. Make a horizontal marking on the handwheel (e.g. with a bit of tape) then turn machine handwheel a further 90°. Now mark position of holder on machine case stiffening rib and position of cutouts in position aid on main shaft. Remove assembly. Glue two Ø1.5mm/height 0.5mm Neodym magnets axially besides each other onto the machine drive shaft, centered between the marks made with the position aid (same magnetic pole facing outwards - if the magnets try to "flee" from each other, you have them right). Bend one wire of the reed contact 90° so that you can insert it into the reed contact holder. It should fit snugly into the excess. Be careful to not apply too much pressure, reed contacts are fragile.Bend rear wires around into outer recesses, bend and shorten frontal wires. Insert cable and reed contact holder into main part. Solder wires to reed contacts, leaving some excess length for alter adjustment. Place holder into machine at the place marked before and secure by tightening grub screw. If you do not own a miniature ratchet, instert bit into screw and carefully turn using pliers. rotate machine with multimeter attached to reed contacts, the contatcs should close when needle is a bottom and at top position. If necessary, fine position reed contacts by rotating reed contact holder - the 2mm rod used before can be inserted into the corresponding hole the get a lever for turning. When done, secure reed contact holder in main part by carefully tightening the grub screw and mount cover with two short (5mm length is good) Ø3mm screws for plastic. The cover secures the cable as well. Printed with PETG (PLA should work as well), without support structures. Print settings: print height: 0,15mm infill: 30% used hotend nozzle size: 0,4mm

With this file you will be able to print Singer Nähmaschine / sewing machine 6xx (670g, 631g, ...) electronic conversion parts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Singer Nähmaschine / sewing machine 6xx (670g, 631g, ...) electronic conversion parts.