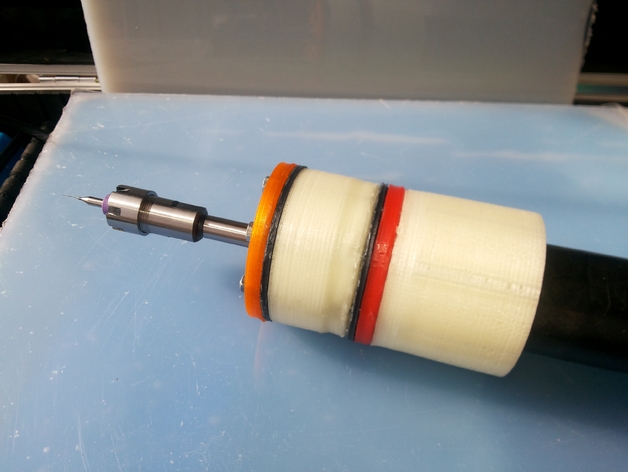

Simple ER11 drill vacuum 52mm turbine

thingiverse

Many thanks go out to harmane for their idea of creating a vacuum turbine tool at http://www.thingiverse.com/harmane/about. I attempt to create it but find the process too complex to print. I decide to design a much simpler turbine, and the external size matches 52mm as found on this eBay item: 300w-12000RPM-Spindle-Motor-Mount-Bracket-12V-48V-Engraver-Cutter-Marker-CNC-/121245097542?pt=LH_DefaultDomain_0&hash=item1c3ac55e46. To create the tool, you need: Two high-speed ball bearings measuring 8x16x5 mm in size and ABEC-7 quality, which is available on eBay at this item: http://www.ebay.com/itm/8x16x5-mm-Stainless-Metal-Shield-Ball-Bearings-ABEC-7-SMR688-ZZ-A7-AF2-/251868279954 One ER11A 8mm Straight Shank Chuck with key, also available on eBay at this item: http://www.ebay.com/itm/C8-ER11M-100L-Straight-Shank-Chuck-Wrench-Deep-Processing-for-CNC-Milling-/191238774516?pt=LH_DefaultDomain_15&hash=item2c86b81ef4 One ER11 1/8" spring collet, available on eBay at this item: http://www.ebay.com/itm/ER11-Spring-Collet-Holder-Tool-for-CNC-Workholding-milling-Lathe-tool-1-8-/291269051426?pt=LH_DefaultDomain_15&hash=item43d0fd0422 Eight M3 60mm long bolts and nuts, available on eBay at this item: http://www.ebay.com/itm/3mm-x-60mm-SLOTTED-CHEESEHEAD-MACHINE-SCREWS-M3-NUTS-AND-WASHERS-NEW-PACK-OF-5-/261041368296?pt=LH_DefaultDomain_3&hash=item3cc7472ce8 Print out 1 turbine housing, 1 vacuum hose, 2 ball bearing holders, 2-4 bearing covers, and 1 turbine blade using Harmane's design found at http://www.thingiverse.com/download:820170. Maybe you will also need some luck, a 3mm drill, and a vacuum. You can modify the SCAD files to match your vacuum hose diameter. Unfortunately, I didn't save my SCAD files for the bearing holder and cover; only STL files are available at this time :(. At this YouTube video http://youtu.be/WSDnS4di9K0, you can see a similar assembly process. Here's how to assemble it: Take a ball bearing and carefully place it inside its holder using a clamp. Repeat for the second ball bearing. Place the shaft in its housing, but be careful not to damage the shaft or its parts. Attach the linear bearings to each end of the shaft and attach them to the holding clamps to position the shaft on a smooth axis. Remove the linear bearings. Mount one bearing cover at each end of the shaft using clamps. Insert assembled shaft into the housing. Use clamps with the first ball-bearing holder inserted in place; secure it by using clamps with linear bearings removed. Mount the second bearing cover to complete the assembly process, following pictures and examples for correct mounting of flange bolts sequence. Safety first! Be careful of moving parts, drills, drill bits, collet nuts, etc. Wear glasses at all times, and please use caution when working on this machine as a precautionary measure. Extremely recommended is that you read the safety manual from ICSA to be well-informed on how to operate this device properly.

With this file you will be able to print Simple ER11 drill vacuum 52mm turbine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Simple ER11 drill vacuum 52mm turbine.