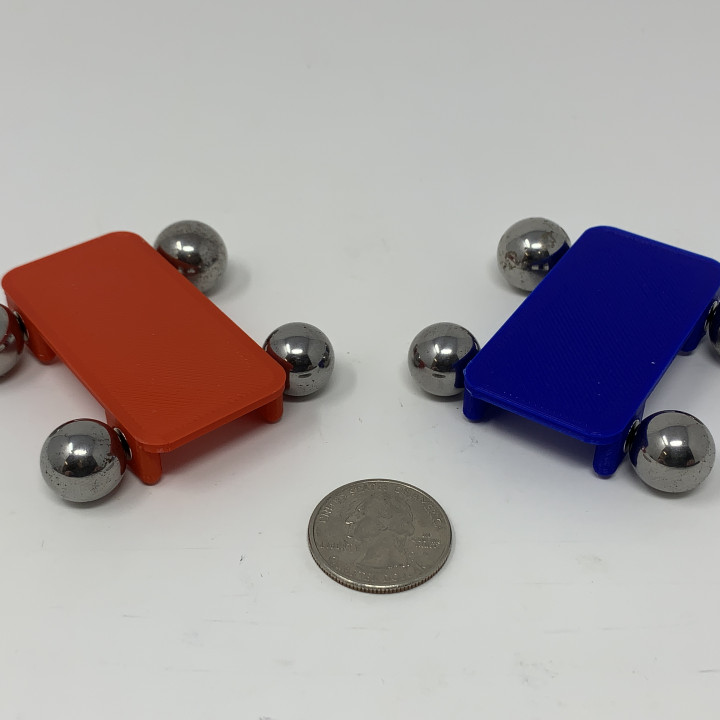

Simple Ball Bearing Car

myminifactory

https://www.youtube.com/watch?v=GLzZMUE9Gac Built from start to finish in under one hour, "Simple Ball Bearing Car" leverages a single-piece 3D printed chassis, four neodymium magnets (6.35mm diameter by 1.6mm thick) and four ball bearings (14.5mm or 9/16" diameter) to create an easy-to-print-and-assemble car that glides smoothly on surfaces. Kids and grandkids can join in on the fun of printing and assembling this project, making it a great first 3D printed endeavor - but check out "One final note..." below. I 3D printed my chassis at .2mm layer height with 20% infill and no supports in about 25 minutes. Next, I used slip joint pliers to press the four neodymium magnets into their magnet sockets within the chassis. Finally, I connected each of the four ball bearings (one per magnet) to the chassis and it was ready to roll! On a smooth wood floor, this model can coast up to 30 feet or further. One final note: the small neodymium magnets and easily separable ball bearings from the chassis require caution around younger kids and grandkids - so please keep an eye on them when handling the car parts (no eating the parts!). Designed using Autodesk Fusion 360, sliced with Cura 4.1 and printed in PLA on both an Ultimaker 2+ Extended and an Ultimaker 3 Extended.

With this file you will be able to print Simple Ball Bearing Car with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Simple Ball Bearing Car.