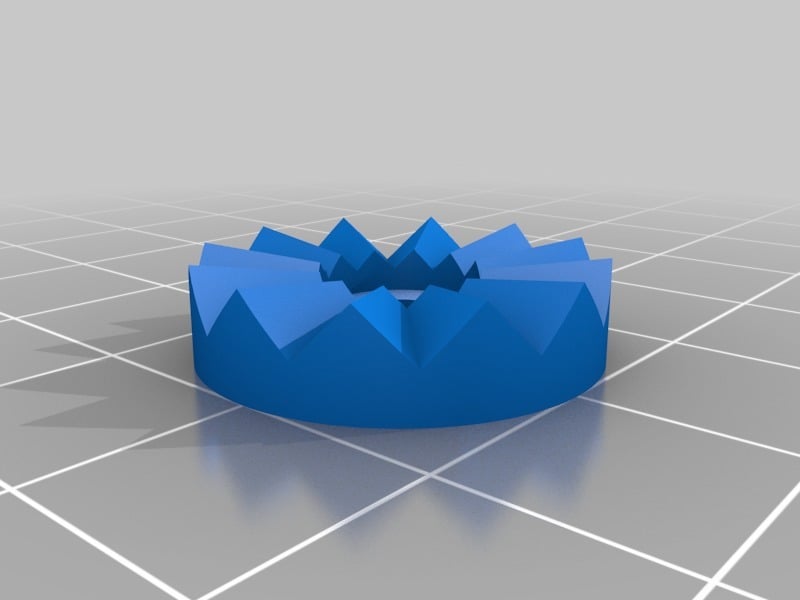

Simple and Accurate Crown Gear (or Hirth Joint) in FreeCAD

thingiverse

Rather than modifying an existing design, you can use these steps to embed a Crown Gear (also known as a Hirth Joint) into your own design. The resulting gear can be merged, cut, and intersected with other shapes. All tooth edges align at a single point at the center. All surfaces are flat to ensure the tooth angle relative to the axis remains consistent throughout each tooth's length. 1. Create a sketch in the XZ-plane for the cross-section of a cylinder. Add shoulders as needed to support recessed screws, and so on. 2. Revolve this sketch into a wedge. Choose an angle such that its product with an even number equals 360; for instance, 15 x 24 = 360. 3. Create a sketch on the outer surface of the wedge. Use the side edges of the wedge as reference geometry. Set the angle of the top edge to the desired gear tooth angle. Only draw half of a tooth. 4. Extrude the new sketch. Set "Along" to a small amount. Set "Against" to the radius of the final gear. 5. Utilize the Common Tool to intersect the two shapes. 6. Create a mirror image of the Common shape in the XZ-plane. 7. Merge the Common shape with its Mirror. 8. Create an Array in Draft Workbench. Set "Merged" = true. Set "Array Type" = Polar. The result is a gear that can be rotated and translated anywhere within the overall design by adjusting its "Base Placement" properties. Revised May 31st, 2018 New procedures provide precise control over the angle of gear teeth.

With this file you will be able to print Simple and Accurate Crown Gear (or Hirth Joint) in FreeCAD with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Simple and Accurate Crown Gear (or Hirth Joint) in FreeCAD.