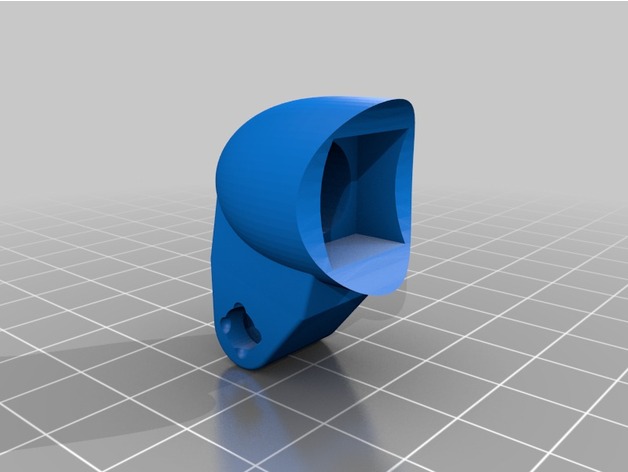

Shifter Cable Downtube Stop

thingiverse

Save yourself money and don't spend $10-20 on these expensive cable stops. They're not worth the cost. Designed for 1.125" downtubes, a common steel tubing size used in many bikes. My bike is from the 1980s and it works fine with this design. If needed, you can use a round file to bring it to a better fit. How I Designed This Based on Shimano's downtube cable stops, I created my own version. I moved the barrel adjuster axis further out to accommodate large diameter barrel adjusters that come with some Shimano stops. These adjusters are small and hard to grip, but larger diameter ones can be tricky to use when they're too close to the downtube. The face with the barrel adjuster has little indents cut out to index with the notches on Shimano barrel adjusters (http://www.chainreactioncycles.com/us/en/shimano-rear-mech-barrel-adjuster/rp-prod8620). I approximated these since they're almost impossible to measure, so best of luck if they work. The captive nut is set in very deep, designed for one approximately 5 mm in height. The max exposed thread on the barrel adjuster is about 8.04 mm, so the thickness between the barrel adjuster face and the nut face must be around 3 mm. This will definitely limit the amount of adjustment available, but it's a necessary consequence of not being able to thread the 3D printed material. Forewarning on the SLDPRT: I accidentally created the barrel adjuster extrusion perpendicular to the downtube axis. I fixed this by deleting the downtube cut-extrude and re-cut extruding in the correct direction. This broke a reference in the barrel adjuster extrusion sketch, and Solidworks still says it's underdefined. I don't know why, but it's still building correctly, so I gave up after about 5 minutes of trying to fix it. Assembly & Materials You'll need a barrel adjuster; cannibalize one from an old RD if you can. The Shimano cable stops come with buttonhead screws that are 10.28 mm long and have a total outside thread diameter of 4.89 mm. Something around that size should work, providing a nice transition with the rest of the cover. You will also need a 4 mm nut; it will fit 99% of heights since the captive depth is very deep. You could use a locknut, but I'm not sure how tight it might be to turn. Ready for 3D printing (no machining version). Use a round file to bring it to a better fit if you need. Updates 17 Jan 17: I did a test print with 0.1 mm layer height and 3.0 mm HIPS on a Lulzbot Mini. The recesses for the barrel adjuster didn't render, but the curvature for the downtube was dead on perfect. I just need to test the fit over a shifter boss. Another concern is that the recess for the nut is very close to the perimeter; it just looks really damn close.

With this file you will be able to print Shifter Cable Downtube Stop with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Shifter Cable Downtube Stop.