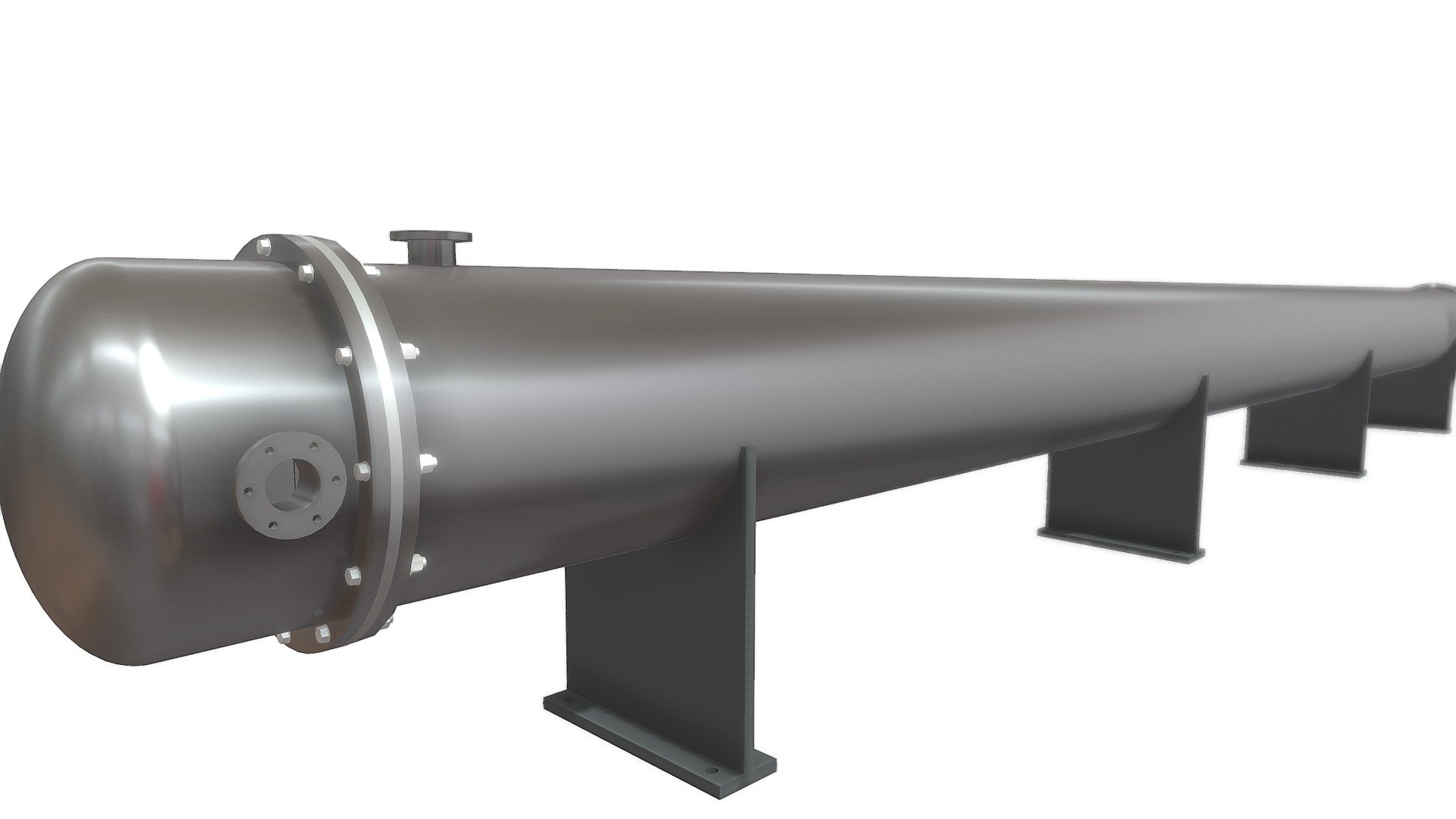

Shell and Tube Heat Exchanger Design

sketchfab

Oil Refineries Optimize Heat Transfer with Advanced Shell and Tube Designs In oil processing operations, efficient heat transfer is paramount to maximizing production yields while minimizing costs. One key component in achieving this goal is the shell and tube heat exchanger, a crucial piece of equipment that plays a vital role in temperature control and product quality. By utilizing advanced design techniques, oil refineries can optimize their shell and tube heat exchangers to meet the unique demands of their specific processes. These designs take into account factors such as fluid dynamics, thermal conductivity, and material selection to ensure maximum efficiency and reliability. A well-designed shell and tube heat exchanger can significantly improve the overall performance of an oil processing plant. By reducing energy consumption and minimizing maintenance requirements, these units enable refineries to operate more efficiently and effectively, ultimately leading to increased profitability and competitiveness in the market. In addition to optimizing heat transfer rates, advanced shell and tube designs also offer improved durability and resistance to corrosion. This is particularly important for oil refineries, where harsh chemicals and high temperatures can take a toll on equipment over time. By incorporating cutting-edge design principles into their shell and tube heat exchangers, oil refineries can ensure that their operations remain safe, efficient, and environmentally friendly. As the demand for cleaner and more sustainable energy continues to grow, innovative designs like these will play an increasingly important role in meeting this challenge.

With this file you will be able to print Shell and Tube Heat Exchanger Design with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Shell and Tube Heat Exchanger Design.