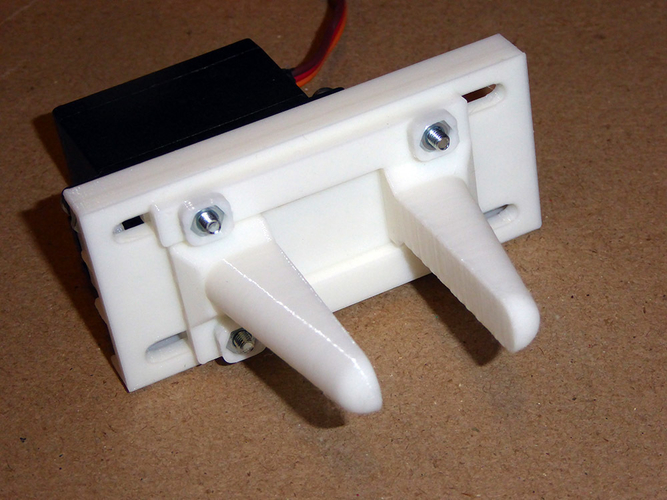

Servo Controlled Robotic Gripper using rack & pinion drive

pinshape

3D Printed Servo Controlled Robotic Gripper using rack & pinion drive for parallel jaw movement. This robotic gripper/jaw uses a low-cost Tower Pro MG996R servo, offering an affordable alternative to more expensive options. Unlike some grippers that rely on lever action, this design directly drives both jaws with a rack and pinion action, resulting in slightly tighter grip and totally parallel jaw movement. Its compact design makes it easily adaptable for use on a robotic arm, expanding its applications in various industries. To assemble the gripper, you will need: 1. Tower Pro MG996R servo motor (approximately $10) 2. M3x15mm screws (4 pieces) 3. M3x10mm screws (4 pieces) 4. M3 nuts (8 pieces) For power supply, a servo motor test board and a USB phone charger (2.5A) are recommended. However, an Arduino can also be used for control. If you're looking to purchase the servo tester board, you can find it online at https://www.banggood.com/Servo-Test-Breakout-Board-for-Servo-Motor-DIY-Kit-p-1431457.html

With this file you will be able to print Servo Controlled Robotic Gripper using rack & pinion drive with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Servo Controlled Robotic Gripper using rack & pinion drive.