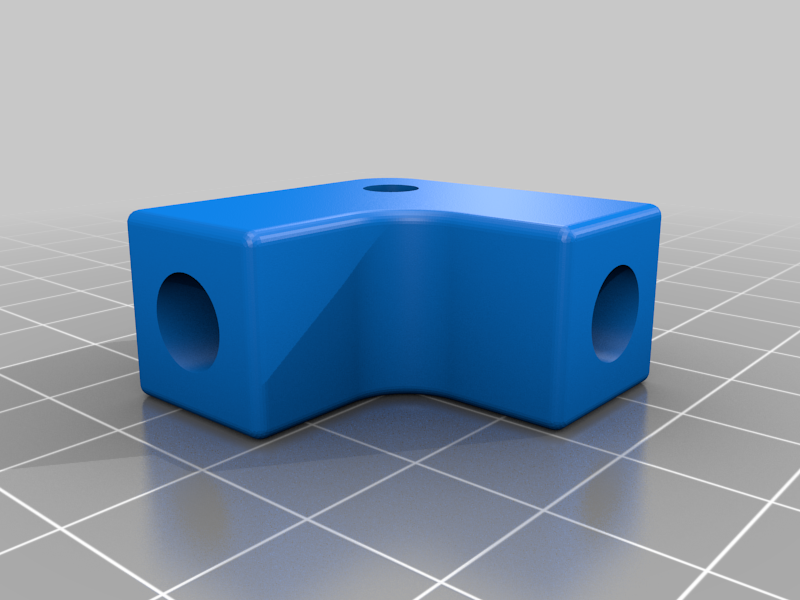

Sequential shifter

thingiverse

Bearing rail is now perfectly aligned with the switchplate, streamlining production by reducing parts to be printed. To achieve this, the mounting plate was shortened since it previously obstructed the bearing rail. A decision needs to be made regarding side covers: print two separate units or a single cover combined with a side cover mount. Required materials include: Two 8mm rods, one placed between the shifter knob and hinge, and the second connecting the hinge to the bearing holder. Two 8mm inner diameter ball bearings measuring 8x7x22mm. Six 4mm bolts, each at least 45mm in length. Two 8mm bolts with a length of approximately 15mm. A suitable spring for optimal performance. A shift knob for smooth operation. Microswitches or magnets and hall effect sensors are necessary; two microswitches with a maximum width of 2 cm or two magnets paired with two hall effect sensors (available on Amazon) will suffice.

With this file you will be able to print Sequential shifter with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Sequential shifter.